Page 130 - QR KLINDEX EXPANDER850AT-RXt

P. 130

MAINTENANCE

10.6 Planetary and satellite 10.7 Greasing

maintenance

For greasing operations, only use the lubricant indi-

Carry out the checks and operations indicated below cated in the table. Use the designated tools such a lu-

every week: bricating pump (not supplied).

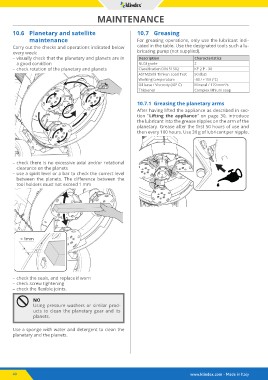

– visually check that the planetary and planets are in

Description Characteristics

a good condition NLGI grade 2

– check rotation of the planetary and planets Classification DIN 51502 KP 2 P - 30

ASTM2509 Timken Load Test 50 (lbs)

Working temperature -30 / +150 (°C)

Oil base / Viscosity (40° C) Mineral / 170 mm2/s

Thickener Complex lithium soap

10.7.1 Greasing the planetary arms

After having lifted the appliance as described in sec-

tion "Lifting the appliance" on page 30, introduce

the lubricant into the grease nipples on the arm of the

planetary. Grease after the first 50 hours of use and

then every 100 hours. Use 30 g of lubricant per nipple.

– check there is no excessive axial and/or rotational

clearance on the planets

– use a spirit level or a bar to check the correct level

between the planets. The difference between the

tool holders must not exceed 1 mm

< 1mm

– check the seals, and replace if worn

– check screw tightening

– check the flexible joints.

d NO

Using pressure washers or similar prod-

ucts to clean the planetary gear and its

planets.

Use a sponge with water and detergent to clean the

planetary and the planets.

40 www.klindex.com - Made in Italy