Page 6 - SSAB Welding Handbook Edition 2

P. 6

©2009-2019 by SSAB Group of companies (SSAB). All rights reserved. Only digital PDF file. No distribution. No printing allowed!

No part of this handbook may be reproduced in any form or by any means without permission in writing from SSAB.

1.0 Index Welding handbook

©SSAB

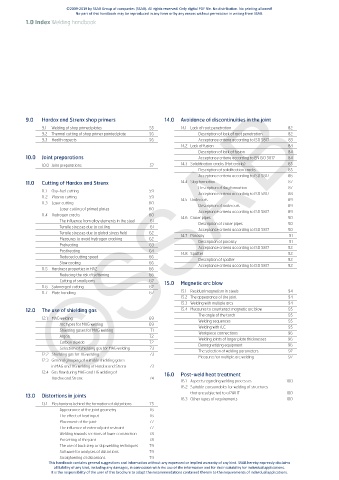

9.0 Hardox and Strenx shop primers 14.0 Avoidance of discontinuities in the joint

9.1 Welding of shop primed plates 55 14.1 Lack of root penetration 82

9.2 Thermal cutting of shop primer painted plate 56 Description of lack of root penetration 82

9.3 Health aspects 56 Acceptance criteria according to ISO 5817 83

14.2 Lack of fusion 84

Description of lack of fusion 84

10.0 Joint preparations Acceptance criteria according to EN ISO 5817 84

10.0 Joint preparations 57 14.3 Solidification cracks (Hot cracks) 85

Description of solidification cracks 85

Acceptance criteria according to ISO 5817 86

11.0 Cutting of Hardox and Strenx 14.4 Slag formation 87

Description of slag formation 87

11.1 Oxy-fuel cutting 59 Acceptance criteria according to ISO 5817 88

11.2 Plasma cutting 59 14.5 Undercuts 89

11.3 Laser cutting 60 Description of undercuts 89

Laser cutting of primed plates 60

Acceptance criteria according to ISO 5817

11.4 Hydrogen cracks 60 14.6 Crater pipes 89

90

The influence from alloy elements in the steel 61 Description of crater pipes 90

Tensile stresses due to cutting 61 Acceptance criteria according to ISO 5817 90

Tensile stresses due to global stress field 62 14.7 Porosity 91

Measures to avoid hydrogen cracking 62 Description of porosity 91

Preheating 63 Acceptance criteria according to ISO 5817 92

Postheating 64 14.8 Spatter 92

Reduced cutting speed 66 Description of spatter 92

Slow cooling 66 Acceptance criteria according to ISO 5817 92

11.5 Hardness properties in HAZ 66

Reducing the risk of softening 66

Cutting of small parts 67 15.0 Magnetic arc blow

11.6 Submerged cutting 67

11.7 Plate handling 67 15.1 Residual magnetism in steels 94

15.2 The appearance of the joint 94

15.3 Welding with multiple arcs 94

12.0 The use of shielding gas 15.4 Measures to counteract magnetic arc blow 95

The angle of the torch 95

12.1 MAG welding 69 Welding sequences 95

Arc types for MAG welding 69 Welding with A.C. 95

Shielding gases for MAG welding 71 Workpiece connections 96

Argon 72 Welding joints of larger plate thicknesses 96

Carbon dioxide 72 Demagnetizing equipment 96

Selection of shielding gas for MAG welding 73 The selection of welding parameters 97

12.2 Shielding gas for TIG welding 73 Measures for multiple arc welding 97

12.3 General grouping of suitable shielding gases

in MAG and TIG welding of Hardox and Strenx 73

12.4 Gas flow during MAG and TIG welding of 16.0 Post-weld heat treatment

Hardox and Strenx 74

16.1 Aspects regarding welding processes 100

16.2 Suitable consumables for welding of structures

that are subjected to a PWHT 100

13.0 Distortions in joints

16.3 Other types of requirements 100

13.1 Mechanisms behind the formation of distortions 75

Appearance of the joint geometry 76

The effect of heat input 76

Placement of the joint 77

The influence of external joint restraint 77

Welding towards sections of lower constriction 78

Presetting of the joint 78

The use of back step or skip welding techniques 79

Software for analyses of distortions 79

Straightening of distortions 79

6 This handbook contains general suggestions and information without any expressed or implied warranty of any kind. SSAB hereby expressly disclaims

all liability of any kind, including any damages, in connection with the use of the information and for their suitability for individual applications.

It is the responsibility of the user of this brochure to adapt the recommendations contained therein to the requirements of individual applications.