Page 16 - May 2020

P. 16

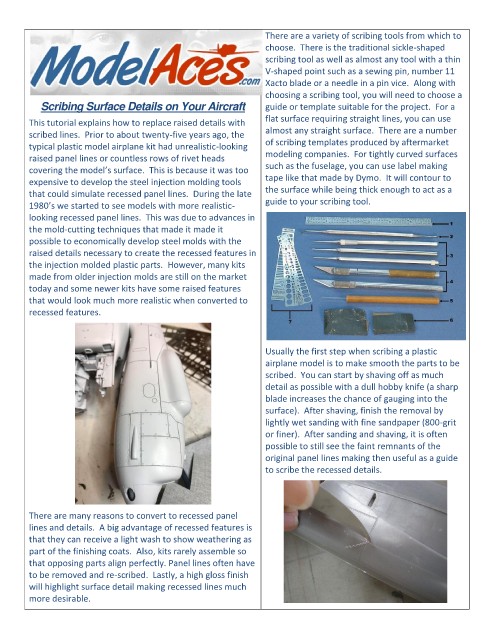

There are a variety of scribing tools from which to

choose. There is the traditional sickle-shaped

scribing tool as well as almost any tool with a thin

V-shaped point such as a sewing pin, number 11

Xacto blade or a needle in a pin vice. Along with

choosing a scribing tool, you will need to choose a

Scribing Surface Details on Your Aircraft guide or template suitable for the project. For a

flat surface requiring straight lines, you can use

This tutorial explains how to replace raised details with

scribed lines. Prior to about twenty-five years ago, the almost any straight surface. There are a number

of scribing templates produced by aftermarket

typical plastic model airplane kit had unrealistic-looking

modeling companies. For tightly curved surfaces

raised panel lines or countless rows of rivet heads

covering the model’s surface. This is because it was too such as the fuselage, you can use label making

tape like that made by Dymo. It will contour to

expensive to develop the steel injection molding tools

the surface while being thick enough to act as a

that could simulate recessed panel lines. During the late

1980’s we started to see models with more realistic- guide to your scribing tool.

looking recessed panel lines. This was due to advances in

the mold-cutting techniques that made it made it

possible to economically develop steel molds with the

raised details necessary to create the recessed features in

the injection molded plastic parts. However, many kits

made from older injection molds are still on the market

today and some newer kits have some raised features

that would look much more realistic when converted to

recessed features.

Usually the first step when scribing a plastic

airplane model is to make smooth the parts to be

scribed. You can start by shaving off as much

detail as possible with a dull hobby knife (a sharp

blade increases the chance of gauging into the

surface). After shaving, finish the removal by

lightly wet sanding with fine sandpaper (800-grit

or finer). After sanding and shaving, it is often

possible to still see the faint remnants of the

original panel lines making then useful as a guide

to scribe the recessed details.

There are many reasons to convert to recessed panel

lines and details. A big advantage of recessed features is

that they can receive a light wash to show weathering as

part of the finishing coats. Also, kits rarely assemble so

that opposing parts align perfectly. Panel lines often have

to be removed and re-scribed. Lastly, a high gloss finish

will highlight surface detail making recessed lines much

more desirable.