Page 153 - booklet draft

P. 153

ENERGY SAVING MEASURES

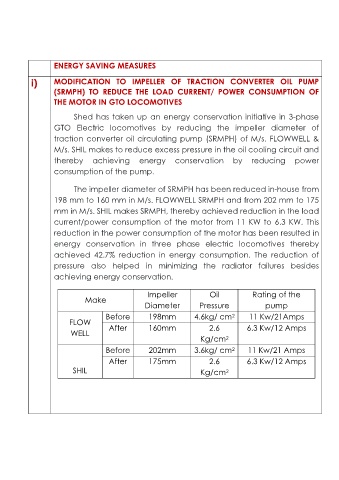

i) MODIFICATION TO IMPELLER OF TRACTION CONVERTER OIL PUMP

(SRMPH) TO REDUCE THE LOAD CURRENT/ POWER CONSUMPTION OF

THE MOTOR IN GTO LOCOMOTIVES

Shed has taken up an energy conservation initiative in 3-phase

GTO Electric locomotives by reducing the impeller diameter of

traction converter oil circulating pump (SRMPH) of M/s. FLOWWELL &

M/s. SHIL makes to reduce excess pressure in the oil cooling circuit and

thereby achieving energy conservation by reducing power

consumption of the pump.

The impeller diameter of SRMPH has been reduced in-house from

198 mm to 160 mm in M/s. FLOWWELL SRMPH and from 202 mm to 175

mm in M/s. SHIL makes SRMPH, thereby achieved reduction in the load

current/power consumption of the motor from 11 KW to 6.3 KW. This

reduction in the power consumption of the motor has been resulted in

energy conservation in three phase electric locomotives thereby

achieved 42.7% reduction in energy consumption. The reduction of

pressure also helped in minimizing the radiator failures besides

achieving energy conservation.

Impeller Oil Rating of the

Make

Diameter Pressure pump

Before 198mm 4.6kg/ cm 2 11 Kw/21Amps

FLOW

WELL After 160mm 2.6 6.3 Kw/12 Amps

Kg/cm 2

Before 202mm 3.6kg/ cm 2 11 Kw/21 Amps

After 175mm 2.6 6.3 Kw/12 Amps

SHIL Kg/cm 2