Page 107 - Training 2019

P. 107

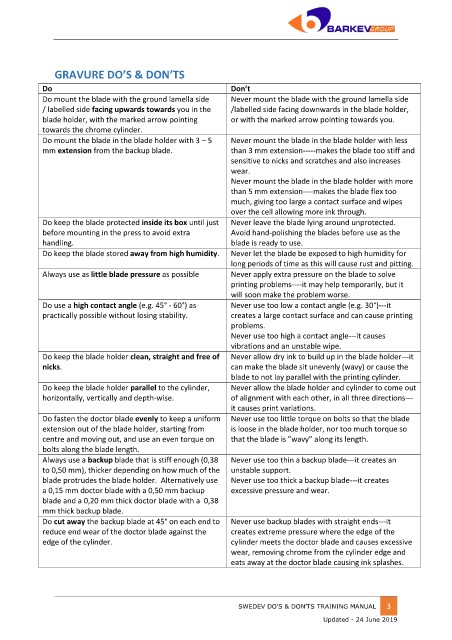

GRAVURE DO’S & DON’TS

Do Don’t

Do mount the blade with the ground lamella side Never mount the blade with the ground lamella side

/ labelled side facing upwards towards you in the /labelled side facing downwards in the blade holder,

blade holder, with the marked arrow pointing or with the marked arrow pointing towards you.

towards the chrome cylinder.

Do mount the blade in the blade holder with 3 – 5 Never mount the blade in the blade holder with less

mm extension from the backup blade. than 3 mm extension-----makes the blade too stiff and

sensitive to nicks and scratches and also increases

wear.

Never mount the blade in the blade holder with more

than 5 mm extension----makes the blade flex too

much, giving too large a contact surface and wipes

over the cell allowing more ink through.

Do keep the blade protected inside its box until just Never leave the blade lying around unprotected.

before mounting in the press to avoid extra Avoid hand-polishing the blades before use as the

handling. blade is ready to use.

Do keep the blade stored away from high humidity. Never let the blade be exposed to high humidity for

long periods of time as this will cause rust and pitting.

Always use as little blade pressure as possible Never apply extra pressure on the blade to solve

printing problems----it may help temporarily, but it

will soon make the problem worse.

Do use a high contact angle (e.g. 45° - 60°) as Never use too low a contact angle (e.g. 30°)---it

practically possible without losing stability. creates a large contact surface and can cause printing

problems.

Never use too high a contact angle---it causes

vibrations and an unstable wipe.

Do keep the blade holder clean, straight and free of Never allow dry ink to build up in the blade holder---it

nicks. can make the blade sit unevenly (wavy) or cause the

blade to not lay parallel with the printing cylinder.

Do keep the blade holder parallel to the cylinder, Never allow the blade holder and cylinder to come out

horizontally, vertically and depth-wise. of alignment with each other, in all three directions---

it causes print variations.

Do fasten the doctor blade evenly to keep a uniform Never use too little torque on bolts so that the blade

extension out of the blade holder, starting from is loose in the blade holder, nor too much torque so

centre and moving out, and use an even torque on that the blade is ”wavy” along its length.

bolts along the blade length.

Always use a backup blade that is stiff enough (0,38 Never use too thin a backup blade---it creates an

to 0,50 mm), thicker depending on how much of the unstable support.

blade protrudes the blade holder. Alternatively use Never use too thick a backup blade---it creates

a 0,15 mm doctor blade with a 0,50 mm backup excessive pressure and wear.

blade and a 0,20 mm thick doctor blade with a 0,38

mm thick backup blade.

Do cut away the backup blade at 45° on each end to Never use backup blades with straight ends---it

reduce end wear of the doctor blade against the creates extreme pressure where the edge of the

edge of the cylinder. cylinder meets the doctor blade and causes excessive

wear, removing chrome from the cylinder edge and

eats away at the doctor blade causing ink splashes.

SWEDEV DO’S & DON’TS TRAINING MANUAL 3

Updated - 24 June 2019