Page 108 - Training 2019

P. 108

Always use a blade oscillation that is as long as (e.g. Never use a short and rapid oscillation---it can cause

10-20 mm), slow and smooth as possible. uneven doctor blade wear at heavy image areas (solid

white panels) and at the edge of cylinders.

Always use printing cylinders with smoothly Never use printing cylinders with sharp and

rounded (polished) ends, conic end of 1 degree at unpolished ends---it causes quick formation of end

15-20 mm in from the cylinder end. wear and blade debris from ends falling into the ink.

Always use chrome cylinders with optimum surface Never use chrome cylinders with too low roughness

roughness (Rz between 0,4 and 0,6). (e.g. if cylinders have been used a long time) which

causes too low friction and can cause local heat

problems, damaging the ink’s function.

Never use too high cylinder roughness which can wear

out the doctor blade too quickly and cause scum or

hazy print problems.

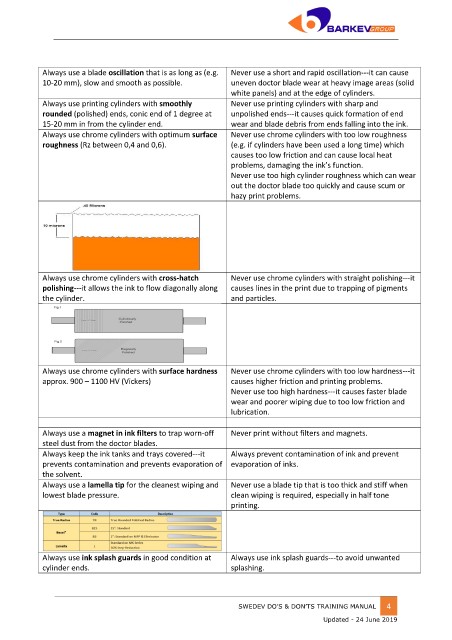

Always use chrome cylinders with cross-hatch Never use chrome cylinders with straight polishing---it

polishing---it allows the ink to flow diagonally along causes lines in the print due to trapping of pigments

the cylinder. and particles.

Always use chrome cylinders with surface hardness Never use chrome cylinders with too low hardness---it

approx. 900 – 1100 HV (Vickers) causes higher friction and printing problems.

Never use too high hardness---it causes faster blade

wear and poorer wiping due to too low friction and

lubrication.

Always use a magnet in ink filters to trap worn-off Never print without filters and magnets.

steel dust from the doctor blades.

Always keep the ink tanks and trays covered---it Always prevent contamination of ink and prevent

prevents contamination and prevents evaporation of evaporation of inks.

the solvent.

Always use a lamella tip for the cleanest wiping and Never use a blade tip that is too thick and stiff when

lowest blade pressure. clean wiping is required, especially in half tone

printing.

Always use ink splash guards in good condition at Always use ink splash guards---to avoid unwanted

cylinder ends. splashing.

SWEDEV DO’S & DON’TS TRAINING MANUAL 4

Updated - 24 June 2019