Page 31 - UNIDO SECiM - 2020 Highlights

P. 31

implementation. The institution is now able to conduct online

and blended trainings. Besides eLearning courses on

Knitwear wet finishing technology, 4 other courses of UNIDO

(Footwear Pattern Engineering, Sustainable Leather

Manufacturing, Leather Testing Method and Sheep shearing)

were uploaded and handed over to the platform for further

business opportunities. https://learning.rdili.edu.mn

Activity 2.3.3.5: Assess ● The project aimed to assess by-products, waste from

production and market industries, and identify potential for adding value to those

potential for additional products (e.g: for cosmetics, insulation etc). Although there is

derived products of the a concrete export market for value added wool by products

wool/cashmere raw and already a business proposal was received through WPO

material or waste (e.g. to Mongolian industry, the COVID 19 lockdown has triggered

wool insulation, to slow down the approval process at HQ of UNIDO and this

stuffing/filling) work was cancelled in the last moment.

Sub-component 2.3 Leather value chain

One of the key achievements under the leather value chain sub-component was the locally

available, reasonable, replicable, and internationally recognized method – zero-defect Static

Flaying Frame (SFF) technology for hides and skins quality improvement was introduced and

upscaled. The Minister of MoFALI participated in person in most of the project interventions

and decided to upscale the supply chain quality improvement actions at national level.

Furthermore, substantial scale of international trainings was conducted for leather industry

stakeholders, especially for tanneries in coordination with UNIDO’s national and international

experts. MALI and AUO played significant roles in delivering the expected results under this

sub component.

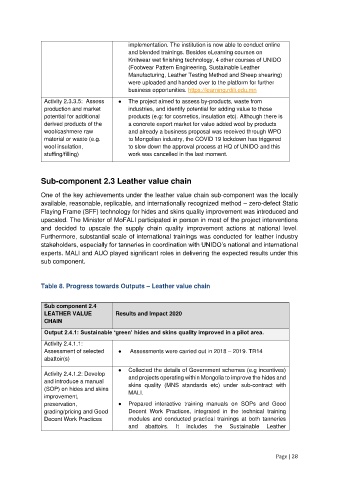

Table 8. Progress towards Outputs – Leather value chain

Sub component 2.4

LEATHER VALUE Results and Impact 2020

CHAIN

Output 2.4.1: Sustainable ‘green’ hides and skins quality improved in a pilot area.

Activity 2.4.1.1:

Assessment of selected ● Assessments were carried out in 2018 – 2019. TR14

abattoir(s)

● Collected the details of Government schemes (e.g incentives)

Activity 2.4.1.2: Develop

and introduce a manual and projects operating within Mongolia to improve the hides and

skins quality (MNS standards etc) under sub-contract with

(SOP) on hides and skins MALI.

improvement,

preservation, ● Prepared interactive training manuals on SOPs and Good

grading/pricing and Good Decent Work Practices, integrated in the technical training

Decent Work Practices modules and conducted practical trainings at both tanneries

and abattoirs. It includes the Sustainable Leather

Page | 28