Page 105 - PIGNAT catalogue 2020 GB_092020

P. 105

SPRAY DRYER

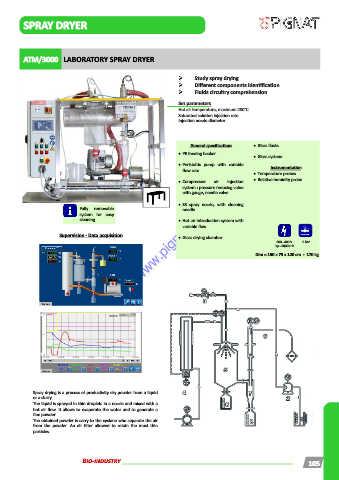

ATM/3000 LABORATORY SPRAY DRYER

➢ Study spray drying

➢ Different components identification

➢ Fluids circuitry comprehension

Set parameters

Hot air temperature, maximum 200°C

Saturated solution injection rate

Injection nozzle diameter

General specifications • Glass flasks.

• PE feeding beaker. • Glass cyclone.

• Peristaltic pump with variable Instrumentation

flow rate.

• Temperature probes.

• Relative humidity probe.

• Compressed air injection

system : pressure reducing value

with gauge, needle valve.

www.pignat.com

www.pignat.com Dim = 150 x 75 x 120 cm - 170 kg

Fully removable • SS spray nozzle, with cleaning

needle.

system for easy

cleaning. • Hot air introduction system with

variable flow.

Supervision - Data acquisition • Glass drying chamber.

5 bar

200 - 400 V

3ϕ - 50/60 Hz

Spray drying is a process of productivity dry powder from a liquid

or a slurry.

The liquid is sprayed in thin droplets in a nozzle and mixed with a

hot air flow. It allows to evaporate the water and to generate a

fine powder.

The obtained powder is carry to the cyclone who separate the air

from the powder. An air filter allowed to retain the most thin

particles.

Bio-industry 105