Page 45 - Final Report - KAUSC Team

P. 45

KAUSC Team

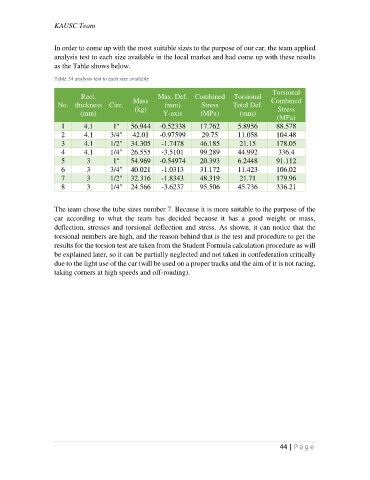

In order to come up with the most suitable sizes to the purpose of our car, the team applied

analysis test to each size available in the local market and had come up with these results

as the Table shows below.

Table 34 analysis test to each size available

Rect. Circ. Mass Max. Def. Combined Torsional Torsional

No. thickness (kg) (mm) Stress Total Def. Combined

1" Y-axis (MPa)

(mm) 3/4" 56.944 (mm) Stress

1/2" 42.01 -0.52338 17.762 (MPa)

1 4.1 1/4" 34.305 -0.97599 29.75 5.8956 88.578

2 4.1 1" 26.555 -1.7478 46.185 11.058 104.48

3 4.1 3/4" 54.969 -3.5101 99.289 21.15 178.05

4 4.1 1/2" 40.021 -0.54974 20.393 44.992 336.4

53 1/4" 32.316 -1.0313 31.172 6.2448 91.112

63 24.566 -1.8343 48.319 11.423 106.02

73 -3.6237 95.506 21.71 179.96

83 45.736 336.21

The team chose the tube sizes number 7. Because it is more suitable to the purpose of the

car according to what the team has decided because it has a good weight or mass,

deflection, stresses and torsional deflection and stress. As shown, it can notice that the

torsional numbers are high, and the reason behind that is the test and procedure to get the

results for the torsion test are taken from the Student Formula calculation procedure as will

be explained later, so it can be partially neglected and not taken in confederation critically

due to the light use of the car (will be used on a proper tracks and the aim of it is not racing,

taking corners at high speeds and off-roading).

44 | P a g e