Page 400 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 400

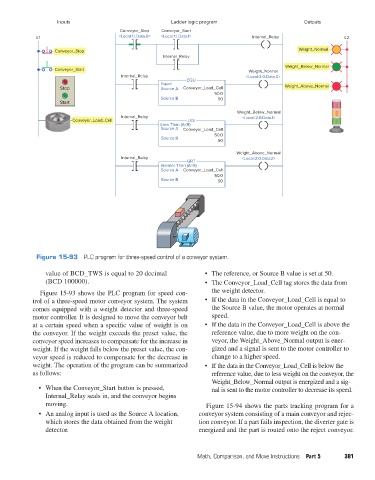

Ladder logic program

Inputs

Conveyor_Stop Conveyor_Start Outputs

L1 <Local:1:I.Data.0> <Local:1:I.Data.1> Internal_Relay L2

Conveyor_Stop Weight_Normal

Internal_Relay

Weight_Below_Normal

Conveyor_Start Weight_Normal

Internal_Relay <Local:2:0.Data.0>

EQU

Equal

Stop Source A Conveyor_Load_Cell Weight_Above_Normal

50.0

Source B 50

Start

Weight_Below_Normal

Internal_Relay <Local:2:0.Data.1>

Conveyor_Load_Cell LES

Less Than (A<B)

Source A Conveyor_Load_Cell

50.0

Source B

50

Weight_Above_Normal

Internal_Relay <Local:2:0.Data2>

GRT

Greater Than (A>B)

Source A Conveyor_Load_Cell

50.0

Source B 50

Figure 15-93 PLC program for three-speed control of a conveyor system.

value of BCD_TWS is equal to 20 decimal • The reference, or Source B value is set at 50.

(BCD 100000). • The Conveyor_Load_Cell tag stores the data from

Figure 15-93 shows the PLC program for speed con- the weight detector.

trol of a three-speed motor conveyor system. The system • If the data in the Conveyor_Load_Cell is equal to

comes equipped with a weight detector and three-speed the Source B value, the motor operates at normal

motor controller. It is designed to move the conveyor belt speed.

at a certain speed when a specific value of weight is on • If the data in the Conveyor_Load_Cell is above the

the conveyor. If the weight exceeds the preset value, the reference value, due to more weight on the con-

conveyor speed increases to compensate for the increase in veyor, the Weight_Above_Normal output is ener-

weight. If the weight falls below the preset value, the con- gized and a signal is sent to the motor controller to

veyor speed is reduced to compensate for the decrease in change to a higher speed.

weight. The operation of the program can be summarized • If the data in the Conveyor_Load_Cell is below the

as follows: reference value, due to less weight on the conveyor, the

Weight_Below_Normal output is energized and a sig-

• When the Conveyor_Start button is pressed, nal is sent to the motor controller to decrease its speed.

Internal_Relay seals in, and the conveyor begins

moving. Figure 15-94 shows the parts tracking program for a

• An analog input is used as the Source A location, conveyor system consisting of a main conveyor and rejec-

which stores the data obtained from the weight tion conveyor. If a part fails inspection, the diverter gate is

detector. energized and the part is routed onto the reject conveyor.

Math, Comparison, and Move Instructions Part 5 381

pet73842_ch15_333-394.indd 381 03/11/15 7:34 PM