Page 401 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 401

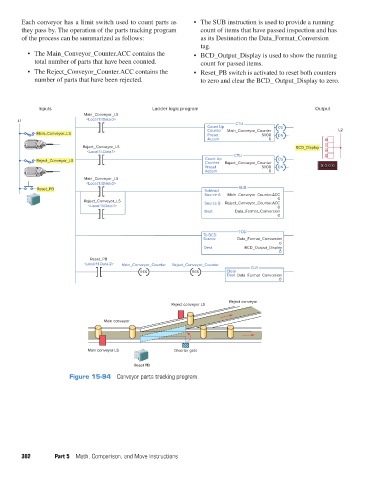

Each conveyor has a limit switch used to count parts as

they pass by. The operation of the parts tracking program • The SUB instruction is used to provide a running

count of items that have passed inspection and has

of the process can be summarized as follows: as its Destination the Data_Format_Conversion

tag.

• The Main_Conveyor_Counter.ACC contains the • BCD_Output_Display is used to show the running

total number of parts that have been counted. count for passed items.

• The Reject_Conveyor_Counter.ACC contains the • Reset_PB switch is activated to reset both counters

number of parts that have been rejected. to zero and clear the BCD_ Output_Display to zero.

Inputs Ladder logic program Output

Main_Conveyor_LS

L1 <Local:1:I.Data.0> CTU

Count Up CU

Counter Main_Conveyor_Counter L2

Main_Conveyor_LS Preset 5000 DN

Accum 0

Reject_Conveyor_LS BCD_Display

<Local:1:I.Data.1>

CTU

Reject_Conveyor_LS Count Up Reject_Conveyor_Counter CU

Counter

Preset 5000 DN 00 0 0

Accum 0

Main_Conveyor_LS

<Local:1:I.Data.0>

Reset_PB Subtract SUB

Source A Main_Conveyor_Counter.ACC

0

Reject_Conveyor_LS Source B Reject_Conveyor_Counter.ACC

<Local:1:I.Data.1> 0

Dest Data_Format_Conversion

0

TOD

To BCD

Source Data_Format_Conversion

0

Dest BCD_Output_Display

0

Reset_PB

<Local:1:I.Data.2> Main_Conveyor_Counter Reject_Conveyor_Counter

CLR

RES RES Clear

Dest Data_Format_Conversion

0

Reject conveyor

Reject conveyor LS

Main conveyor

Main conveyor LS Diverter gate

Reset PB

Figure 15-94 Conveyor parts tracking program.

382 Part 5 Math, Comparison, and Move Instructions

pet73842_ch15_333-394.indd 382 03/11/15 7:34 PM