Page 41 - Buy Premium Tools ATORN Catalogue

P. 41

Drilling tools

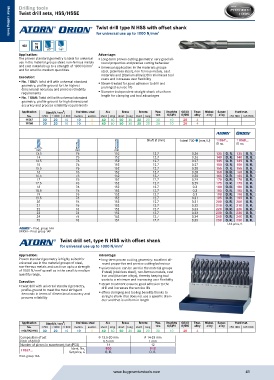

Twist drill sets, HSS/HSSE

Twist drill type N HSS with offset shank

for universal use up to 1000 N/mm 2

Metal cutting tools

Metal cutting tools

Typ

HSS N

3xD 118°

Application: Advantage:

The proven standard geometry is ideal for universal Long-term proven cutting geometry: very good all-

use in the material groups steel, non-ferrous metals round properties and precise cutting behaviour

and cast materials up to a strength of 1000 N/mm 2 Universal application: in the materials groups

and for small to medium quantities. steel, (stainless steel), non-ferrous metals, cast

Execution: materials and (titanium alloys); this minimises tool

costs and increases user flexibility

No. 11067: Twist drill with universal standard Steam-treated for good adhesion to drill and

geometry, profile-ground for the highest prolonged service life

dimensional accuracy and process reliability

requirements Diameter-independent straight shank of uniform

No. 11068: Twist drill with universal standard length for clamping and tool advantages

geometry, profile-ground for high dimensional

accuracy and process reliability requirements

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11067 30 20 10 10 8 40 60 50 30 30 20 20 10 20 4

11068 30 20 10 10 8 40 60 50 30 30 20 20 10 20 4

Shaft Ø (mm) f steel 700 (mm/U) 11067... 11068...

ID no. ID no.

mm mm mm

13.5 76 152 12.7 0.26 135 O. R. 135 O. R.

14 76 152 12.7 0.26 140 O. R. 140 O. R.

14.5 76 152 12.7 0.27 145 O. R. 145 O. R.

15 76 152 12.7 0.27 150 O. R. 150 O. R.

15.5 76 152 12.7 0.28 155 O. R. 155 O. R.

16 76 152 12.7 0.28 160 O. R. 160 O. R.

16.5 76 152 12.7 0.28 165 O. R. 165 O. R.

17 76 152 12.7 0.29 170 O. R. 170 O. R.

17.5 76 152 12.7 0.29 175 O. R. 175 O. R.

18 76 152 12.7 0.3 180 O. R. 180 O. R.

18.5 76 152 12.7 0.3 185 O. R. 185 O. R.

19 76 152 12.7 0.3 190 O. R. 190 O. R.

19.5 76 152 12.7 0.31 195 O. R. 195 O. R.

20 76 152 12.7 0.31 200 O. R. 200 O. R.

21 76 152 12.7 0.32 210 O. R. 210 O. R.

22 76 152 12.7 0.33 220 O. R. 220 O. R.

23 76 152 12.7 0.33 230 O. R. 230 O. R.

24 76 152 12.7 0.34 240 O. R. 240 O. R.

25 76 152 12.7 0.35 250 O. R. 250 O. R.

Unit price, €

a = Prod. group 1AA

ORION = Prod. group 1AP

Twist drill set, type N HSS with offset shank

for universal use up to 1000 N/mm 2

Application: Advantage:

Proven standard geometry is highly suited for long-term proven cutting geometry: excellent all-

universal use in the material groups of steel, round properties and precise cutting behaviour

non-ferrous metals and cast iron up to a strength universal use: can be used in the material groups

2

of 1000 N/mm as well as in the small to medium if steel, (stainless steel), non-ferrous metals, cast

quantity range. iron and (titanium alloys), thereby keeping tool

Execution: costs to a minimum and increasing user flexibility

twist drill with universal standard geometry, steam treatment ensures good adhesion to the

drill and increases the service life

profile-ground to meet the most stringent

demands in terms of dimensional accuracy and offers clamping and tooling benefits thanks to

process reliability straight shank that does not use a specific diam-

eter and that is uniform in length

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11067900-910 30 20 10 10 8 40 60 50 30 30 20 20 10 20 4

Composition of set ∅ 13.5-20 mm ∅ 14-25 mm

Pitch of drill Ø 0.5 mm 1 mm

Number of pieces in assortment/set (PCS) 14 12

910

900

Ident. No.

11067... Set price, € O. R. O. R.

Prod. group 1AA

www.buypremiumtools.com 41