Page 50 - Buy Premium Tools ATORN Catalogue

P. 50

Drilling tools

Micro drill

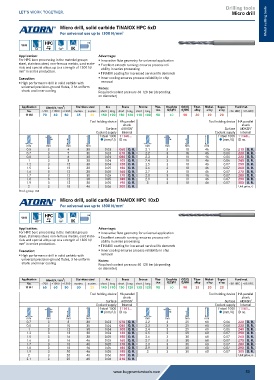

Micro drill, solid carbide TiNAlOX HPC 6xD Metal cutting tools

For universal use up to 1300 N/mm 2

HPC HA

VHM UNI

5xD 130° IK

Application: Advantage:

For HPC bore processing in the material groups Innovative flute geometry for universal application

steel, stainless steel, non-ferrous metals, cast mate- Excellent smooth running: ensures process reli-

rials and special alloys up to a strength of 1300 N/ ability in series processing

mm in series production.

2

TiNAlOX coating for increased service life demands

Execution: Inner cooling ensures process reliability in chip

High performance drill in solid carbide with removal

universal precision-ground flutes, 3 h6 uniform Notes:

shank and inner cooling Required coolant pressure 60-120 bar (depending

on diameter)

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11140 70 60 50 35 30 150 190 150 120 110 100 50 40 90 30 20 20

Tool holding device HA parallel Tool holding device HA parallel

shank shank

Surface AlOXSN 2 Surface AlOXSN 2

Coolant supply Internal Coolant supply Internal

f steel 1000 11140... f steel 1000 11140...

h6 (mm/U) ID no. h6 (mm/U) ID no.

mm mm mm mm mm mm mm mm

0.5 3 4 38 0.03 050 O. R. 2.1 3 18 46 0.06 210 O. R.

0.7 3 5 38 0.03 070 O. R. 2.2 3 18 46 0.06 220 O. R.

0.8 3 6 38 0.04 080 O. R. 2.3 3 18 46 0.06 230 O. R.

1 3 8 38 0.04 100 O. R. 2.4 3 18 46 0.06 240 O. R.

1.2 3 12 38 0.04 120 O. R. 2.5 3 18 46 0.07 250 O. R.

1.5 3 12 38 0.05 150 O. R. 2.6 3 18 46 0.07 260 O. R.

1.6 3 12 38 0.05 160 O. R. 2.7 3 18 46 0.07 270 O. R.

1.7 3 12 38 0.05 170 O. R. 2.8 3 18 46 0.07 280 O. R.

1.8 3 12 38 0.05 180 O. R. 2.9 3 18 46 0.07 290 O. R.

1.9 3 12 38 0.05 190 O. R. 3 3 18 46 0.07 300 O. R.

2 3 18 46 0.06 200 O. R. Unit price, €

Prod. group 134

Micro drill, solid carbide TiNAlOX HPC 10xD

For universal use up to 1300 N/mm 2

HPC HA

VHM UNI

10xD 130° IK

Application: Advantage:

For HPC bore processing in the material groups Innovative flute geometry for universal application

steel, stainless steel, non-ferrous metals, cast mate- Excellent smooth running: ensures process reli-

rials and special alloys up to a strength of 1300 N/ ability in series processing

mm in series production.

2

TiNAlOX coating for increased service life demands

Execution: Inner cooling ensures process reliability in chip

High performance drill in solid carbide with removal

universal precision-ground flutes, 3 h6 uniform Notes:

shank and inner cooling Required coolant pressure 60-120 bar (depending

on diameter)

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11141 65 60 50 30 25 140 190 150 120 130 120 90 60 90 25 20 20

Tool holding device HA parallel Tool holding device HA parallel

shank shank

Surface AlOXSN 2 Surface AlOXSN 2

Coolant supply Internal Coolant supply Internal

f steel 1000 11141... f steel 1000 11141...

h6 (mm/U) ID no. h6 (mm/U) ID no.

mm mm mm mm mm mm mm mm

0.7 3 8 38 0.03 070 O. R. 2.2 3 25 60 0.06 220 O. R.

0.8 3 10 38 0.04 080 O. R. 2.3 3 25 60 0.06 230 O. R.

1 3 12 38 0.04 100 O. R. 2.4 3 25 60 0.06 240 O. R.

1.2 3 12 38 0.04 120 O. R. 2.5 3 25 60 0.07 250 O. R.

1.5 3 16 38 0.05 150 O. R. 2.6 3 30 60 0.07 260 O. R.

1.6 3 16 46 0.05 160 O. R. 2.7 3 30 60 0.07 270 O. R.

1.7 3 18 46 0.05 170 O. R. 2.8 3 30 60 0.07 280 O. R.

1.8 3 18 46 0.05 180 O. R. 2.9 3 30 60 0.07 290 O. R.

1.9 3 20 46 0.05 190 O. R. 3 3 30 60 0.07 300 O. R.

2 3 20 46 0.06 200 O. R. Unit price, €

2.1 3 25 60 0.06 210 O. R.

www.buypremiumtools.com 50