Page 92 - Buy Premium Tools ATORN Catalogue

P. 92

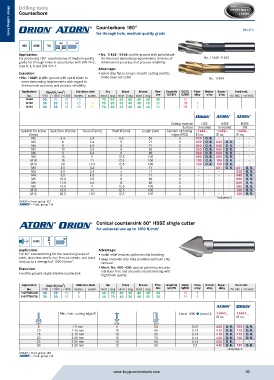

Drilling tools

Counterbore

Counterbore 180° DIN 373

for through hole, medium quality grade

Metal cutting tools

Metal cutting tools

180° HA

HSS HSSE TiN

Application: No. 11452–11454: profile-ground with spiral blade

For producing 180° counterbores of medium quality for the most demanding requirements in terms of No. 11449–11452

grade for through holes in accordance with DIN 74-2, dimensional accuracy and process reliability

type H, J, K and DIN 974-1.

Advantage:

Execution: spiral chip flutes ensure smooth cutting and the

No. 11449: profile-ground with spiral blade to blade does not catch No. 11454

meet demanding requirements with regard to

dimensional accuracy and process reliability

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11449 30 20 10 10 70 80 45 40 40 40 30 15

11452 30 20 10 10 10 70 80 45 40 40 40 30 15 7

11454 30 20 10 10 10 70 80 45 40 40 40 30 15 7

Cutting material HSS HSSE HSSE

Surface Uncoated Uncoated TiN

Suitable for screw Spot-facer Ø (mm) Tenon Ø (mm) Shaft Ø (mm) Length (mm) Number of cutting 11449... 11452... 11454...

thread edges (PCS) ID no. ID no. ID no.

M2 4.3 2.4 4.3 56 3 020 O. R. - - - -

M3 6 3.4 5 71 3 030 O. R. 030 O. R. - -

M4 8 4.5 5 71 3 040 O. R. 040 O. R. - -

M5 10 5.5 8 80 3 050 O. R. 050 O. R. - -

M6 11 6.6 8 80 3 060 O. R. 060 O. R. - -

M8 15 9 12.5 100 3 080 O. R. 080 O. R. - -

M10 18 11 12.5 100 3 100 O. R. 100 O. R. - -

M12 20 13.5 12.5 100 3 120 O. R. 120 O. R. - -

M3 6.5 3.4 5 71 3 - - 031 O. R. 031 O. R.

M3 6.0 3.4 5 71 3 - - - - 030 O. R.

M4 8.0 4.5 5 71 3 - - - - 040 O. R.

M5 10.0 5.5 8 80 3 - - - - 050 O. R.

M6 11.0 6.6 8 80 3 - - - - 060 O. R.

M8 15.0 9 12.5 100 3 - - - - 080 O. R.

M10 18.0 11 12.5 100 3 - - - - 100 O. R.

M12 20.0 13.5 12.5 100 3 - - - - 120 O. R.

Unit price, €

ORION = Prod. group 103

a = Prod. group 114

Conical countersink 60° HSSE single cutter

for universal use up to 1300 N/mm 2

Z HA

HSSE

1

Application: Advantage:

For 60° counterboring for the material groups of radial relief ensures optimum chip breaking

steel, (stainless steel), non-ferrous metals, and (cast deep and wide chip flute provides optimum chip

iron) up to a strength of 1300 N/mm . 2 removal

Execution: Ident. No. 405–430: special geometry ensures

profile-ground single-bladed countersink vibration-free and accurate countersinking with

high finish quality

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11497405-430 30 20 10 8 40 70 60 50 40 30 30 15 8

11497705-730 30 20 10 8 40 70 60 50 40 30 30 15 8

Min./max. cutting edge Ø f steel 1000 (mm/U) 11497... 11497...

ID no. ID no.

mm mm mm

5 1-5 mm 5 50 0.07 405 O. R. 705 O. R.

10 1-10 mm 10 60 0.12 410 O. R. 710 O. R.

15 2-15 mm 10 65 0.14 415 O. R. 715 O. R.

20 2-20 mm 10 73 0.16 420 O. R. 720 O. R.

25 2-25 mm 10 80 0.16 425 O. R. - -

30 3-30 mm 12 82 0.2 430 O. R. 730 O. R.

Unit price, €

ORION = Prod. group 103

a = Prod. group 114

www.buypremiumtools.com 92