Page 546 - Environment: The Science Behind the Stories

P. 546

2 Material is poured into

a crushing machine.

Storage

silo

Crusher Rotary

breaker

Separation

Unit

Froth 3 Hot water

treatment is added.

1 Deposits are

strip-mined.

4 Bitumen rises

to top of slurry.

5 Bitumen is skimmed off,

mixed with solvents, and

6 Synthetic crude is processed into synthetic

piped to a refinery. crude oil. 1 Steam and solvents

Oil sands are injected into

underground deposits

2 Liquefied bitumen

is pumped up to

surface

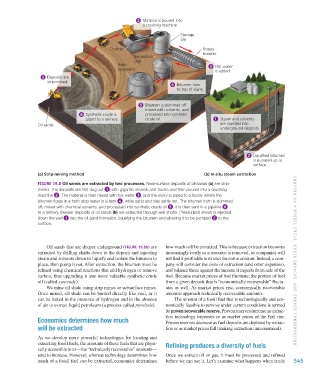

(a) Strip-mining method (b) In-situ steam extraction

FIGURE 19.8 Oil sands are extracted by two processes. Near-surface deposits of oil sands (a) are strip-

mined. The deposits are first dug out 1 with gigantic shovels and trucks and then poured into a crushing

machine 2 . The material is then mixed with hot water 3 , and the slurry is piped to a facility where the

bitumen floats in a froth atop water in a tank 4 , while sand and clay settle out. The bitumen froth is skimmed

off, mixed with chemical solvents, and processed into synthetic crude oil 5 ; it is then sent in a pipeline 6

to a refinery. Deeper deposits of oil sands (b) are extracted through well shafts. Pressurized steam is injected

down the well 1 into the oil sand formation, liquefying the bitumen and allowing it to be pumped 2 to the

surface.

Oil sands that are deeper underground (FIGURE 19.8b) are how much will be extracted. This is because extraction becomes

extracted by drilling shafts down to the deposit and injecting increasingly costly as a resource is removed, so companies will

steam and solvents down to liquefy and isolate the bitumen in not find it profitable to extract the entire amount. Instead, a com- CHAPTER 19 • FOSSIL FUELS, THEIR IMPA CT S, AND ENERGY CONSERVATI ON

place, then pump it out. After extraction, the bitumen must be pany will consider the costs of extraction (and other expenses),

refined using chemical reactions that add hydrogen or remove and balance these against the income it expects from sale of the

carbon, thus upgrading it into more valuable synthetic crude fuel. Because market prices of fuel fluctuate, the portion of fuel

oil (called syncrude). from a given deposit that is “economically recoverable” fluctu-

We mine oil shale using strip mines or subsurface mines. ates as well. As market prices rise, economically recoverable

Once mined, oil shale can be burned directly like coal, or it amounts approach technically recoverable amounts.

can be baked in the presence of hydrogen and in the absence The amount of a fossil fuel that is technologically and eco-

of air to extract liquid petroleum (a process called pyrolysis). nomically feasible to remove under current conditions is termed

its proven recoverable reserve. Proven reserves increase as extrac-

Economics determines how much tion technology improves or as market prices of the fuel rise.

Proven reserves decrease as fuel deposits are depleted by extrac-

will be extracted tion or as market prices fall (making extraction uneconomical).

As we develop more powerful technologies for locating and

extracting fossil fuels, the amounts of these fuels that are physi- Refining produces a diversity of fuels

cally accessible to us—the “technically recoverable” amounts—

tend to increase. However, whereas technology determines how Once we extract oil or gas, it must be processed and refined

much of a fossil fuel can be extracted, economics determines before we can use it. Let’s examine what happens when crude 545

M19_WITH7428_05_SE_C19.indd 545 12/12/14 5:22 PM