Page 155 - Microsoft Word - 2_Inch_Drain_Adapter_PDS_2016_01_05

P. 155

DURO-GRIP BOARD-MAX INSULATION ADHESIVE

®

DETERMINING BEAD SPACING: 8. Do not use on any roof deck that shows signs of

1. Apply Board-Max per the “Directions for Use” deterioration or loss of integrity.

section. 9. Do not use on excessively dirty or grease laden

2. For any project located in an area with the design surfaces.

wind speed greater than 110 mph or a roof deck 10. Do not use after expiration date.

height greater than 60 feet, the Duro-Last

Engineering Services Department must determine STORAGE AND HANDLING:

the bead spacing pattern to be used. Otherwise, 1. The “A” and “B” containers should be stored

use the guidelines below. between 60 and 90° F (16 – 32° C). The shelf life

3. The spacing between beads of Board-Max is less at these temperatures is 12 months from the date

in the perimeter area of the roof than in the main of production.

field area to compensate for higher wind uplift 2. Follow instructions on the “A” and “B” boxes for

pressures. overnight and longer term storage.

4. The width of the perimeter area is defined as the

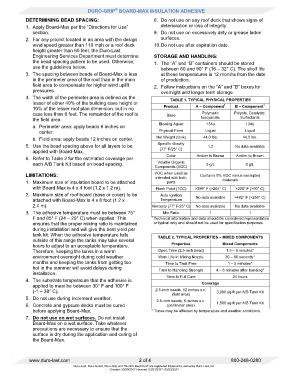

lesser of either 40% of the building eave height or TABLE 1. TYPICAL PHYSICAL PROPERTIES 1

1

10% of the lesser roof plan dimension, but in no Product A – Component B – Component

case less than 6 feet. The remainder of the roof is Base Polymeric Polyols, Catalysts,

the field area. Isocyanate Surfactants

Blowing Agent 134a 134a

a. Perimeter area: apply beads 6 inches on

center. Physical Form Liquid Liquid

b. Field area: apply beads 12 inches on center. Net Weight (tank) 44.0 lbs. 44.0 lbs.

Specific Gravity

5. Use the bead spacing above for all layers to be 1.2 No data available

applied with Board-Max. (77° F/25° C)

Color Amber to Brown Amber to Brown

6. Refer to Table 2 for the estimated coverage per

each A/B Tank Kit based on bead spacing. Volatile Organic 0 g/L 0 g/L

Compounds (VOC)

LIMITATIONS: VOC when used as Contains 0% VOC minus exempted

intended with both

1. Maximum size of insulation board to be attached parts materials

with Board-Max is 4 x 4 foot (1.2 x 1.2 m). Flash Point (TCC) >399° F (>204° C) >200° F (>93° C)

2. Maximum size of roof board (base or cover) to be Auto Ignition

attached with Board-Max is 4 x 8 foot (1.2 x Temperature No data available >482° F (>250° C)

2.4 m). Viscosity (77° F/25° C) No data available No data available

3. The adhesive temperature must be between 75° Mix Ratio 1 1

F and 85° F (24 – 29° C) when applied. This 1 Technical information and data should be considered representative

ensures that the proper mixing ratio is maintained or typical only and should not be used for specification purposes.

during installation and will give the best yield per

tank kit. When the adhesive temperature falls

outside of this range the tanks may take several TABLE 2. TYPICAL PROPERTIES – MIXED COMPONENTS

hours to adjust to an acceptable temperature. Properties Mixed Components

Therefore, keeping the tanks in a warm Open Time (2.5-inch bead) 1.5 – 5 minutes*

environment overnight during cold weather Work Life in Mixing Nozzle 30 – 60 seconds*

months and keeping the tanks from getting too Time to Tack Free 1 – 5 minutes*

hot in the summer will avoid delays during Time to Handling Strength 4 – 8 minutes after bonding*

installation.

Time to Full Cure 24 hours

4. The substrate temperature that the adhesive is

applied to must be between 30° F and 100° F Coverage

(-1 – 38° C). 2.5-inch beads, 12 inches o.c. 3,000 sq-ft per A/B Tank Kit

(field area)

5. Do not use during inclement weather.

2.5-inch beads, 6 inches o.c.

6. Concrete and gypsum decks must be cured (perimeter area) 1,500 sq-ft per A/B Tank Kit

before applying Board-Max. * Times may be affected by temperature and weather conditions.

7. Do not use on wet surfaces. Do not install

Board-Max on a wet surface. Take whatever

precautions are necessary to ensure that the

surface is dry during the application and curing of

the Board-Max.

www.duro-last.com 2 of 4 800-248-0280

Duro-Last, Duro-Guard, Duro-Grip and “World’s Best Roof” are registered trademarks owned by Duro-Last, Inc.

Created: 03/20/2017 Revised: 03/21/2017, 03/23/2017