Page 17 - PPAP submission requirements (PPAP check sheet)

P. 17

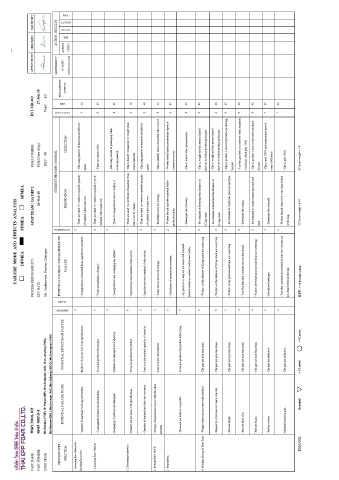

FAILURE MODE AND EFFECTS ANALYSIS

DFMEA PFMEA SFMEA

PART NAME: TRAY,TOOL KIT PROCESS RESPONSIBILITY: APQP TEAM / QA DEPT. FMEA NUMBER: EST-MR-002 APPROVED BY CHECKED ISSUED BY

PART NUMBER: 49401-A0010-A KEY DATE: 15-Oct-19 FMEA Date (Orig.): 27-Jan-18

CORE TEAM: Mr.Worajuk (PDE), Mr Panya (MP), Mrs.Sudaporn (QA), Mrs.Lamyong (PDA), Mr. Janthaworn Factory Manager REV.: 00 Page: 1/3

Ms.Wannee (DEL), Ms.Uraiwan (AM), Mrs.Sukanya (DCO), Mr.Tanongsak (ENG)

PROCESS STEP / POTENTIAL FAILURE MODE POTENTIAL EFFECT(S) OF FAILURE POTENTIAL CAUSE(S) / MECHANISM(S) OF CURRENT PROCESS CONTROL RECOMMENDED RESPONSIBILITY ACTION RESULTS

& TARGET

FUNCTION SEVERITY CLASS FAILURE OCCURANCE PREVENTION DETECTION DETECTION RPN ACTION(S) COMPLETION DATE ACTION SEV. OCCUR. DETECT. RPN

TAKEN

1. Incoming Raw Material & 2 2

Incoming Inspection - Quantity of material receiving are broken. - Product of part are lost from spectification. - Transportation of material from supplier are mistaken. - There are label by vender to specific quantity - Checking quantity of material and label to 8 32

of material when hand over. equal.

1.1.Incoming Raw Material - Consingment of material are mistaken. - It can not produce the product. 5 - There are mistaken of supply 2 - There are label by vender to specific type of - There are check 100% 6 60

material when hand over.

3 2

- Checking outside of packaging when

- Packaging of material are damaged. - Material are damaged to be abrasion. - Transportation and packaging are ruffled. - There is transportation test to confirm it. 8 48

receiving material.

1.2 Incoming Inspection 6 1 - There are send the certificate of material when - Check density of material by weight when

- Density are not same with specification. - It can not produce the product. - Supplier have not standard of take action. 6 36

hand over by vender. recieve material.

3 2 - There are label by vender to specific quantity - Checking quantity of material and label to

- Quantity of material and label are not same. - Lost time for recheck quantity of material. - Supplier have not standard of take action. 8 48

of material when hand over. equal.

2. Storage(Raw Mat'l) - Storage of material are mixed with the other 2 2

material - Lost time for find material. - There are not layout for storage. - Establish layout for storage. - Check identify sheet of material when store it. 8 32

3. Preparation 5 2 - Worker should calculate material follow - Worker should make pre-pesurize report of

- Calculation of material are mistaken. 6 60

production plan. material everyday.

- There are not material to product. - It can not produce the product follow plan. 5 1

- Air pressure in tank are not same with standard 8 40

because breeze in control machine are broken. - Determine life of breeze. - Check breeze when pre-pessurize.

5 2 - Set standard of determine the distance of - Check weight and dimention of part 1 6 60

4. Machine Set-up & First Trial - Weight of part are not same with standard. - The part are non-functional. - Worker set the distance of filling crack not correcting

filling crack. shot/cavity before producing the part.

- Set standard of determine the distance of - Check weight and dimention of part 1

- Dimension of part are not same standard. - The part are non-functional. 6 - Worker set the distance of filling crack not correcting 2 4 48

filling crack. shot/cavity before producing the part.

5 2 - Check product 1 shot/cavity before producing 6 60

- Part are shrink - The part are non-functional. - Worker set air pressure and time not correcting. - Set standard to control air pressure and time.

the part.

4 2 - Test the gun that shot material when assemble 6 48

- Part are short shot. - The part are non-functional. - The Gun that shot material are non-functional. - Determine life of gun.

mould and check part 100%

4 2 - Set standard to control stream pressure and - Check product 1 shot/cavity before produce 6 48

- Part are fusion. - The part are non-functional. - Worker set stream pressure and time not correcting.

time. the part.

3 3 - Check part 100% and maintenance mould 7 63

- Part have burrs - The part are defective. - Mould are breakaged - Determine life of mould.

every 4,000 shots

3 2 7 42

- The other material are residual in tube but workers are - Worker should clean tube every time before

- Material mixed in part. - The part are defective. - Check part 100%

not clean before producing. producing.

REMARK: Symbol = CC point = SC point RPN > 72 To take action CC Score weight = 9-10 SC Score weight = 7-8