Page 22 - PPAP submission requirements (PPAP check sheet)

P. 22

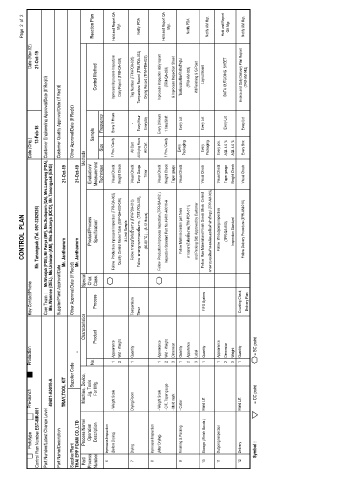

CONTROL PLAN Page 2 of 2

Prototype Pre-launch Production Key Contact/Phone Date (Orig.) Date (Rev.02)

Control Plan Number EST-MR-001 Mr. Tanongsak (Tel. 097-3282926) 13-Feb-18 21-Oct-19

Part Number/Latest Change Level Core Team : Mr.Worajuk (PDE), Mr Panya (MP), Mrs.Sudaporn (QA), Mrs.Lamyong (PDA), Customer Engineering Approval/Date (If Req'd)

49401-A0010-A Ms.Wannee (DEL), Ms.Uraiwan (AM), Mrs.Sukanya (DCO), Mr.Tanongsak (ENG)

Part Name/Description Supplier/Plant Approval/Date Customer Quality Approval/Date (If Req'd)

TRAY,TOOL KIT Mr. Janthaworn 21-Oct-19

Supplier/Plant Supplier Code Other Approval/Date (If Req'd) Other Approval/Date (If Req'd)

THAI EPP FOAM CO.,LTD - Mr. Janthaworn 21-Oct-19

Part/ Process Name/ Machine, Device, Characteristics Special Methods

Process Operation Jig, Tools No. Char. Product/Process Evaluation/ Sample Reaction Plan

Number Description For Mfg. Product Process Class. Specification/ Measurement Control Method

Technique Size Frequency

6 Inprocess Inspection

(Before Drying) - Weight Scale 1 Appearance Follow Production Inprocess Inspection (TPR-QA-002) Visual Check 1 Pcs./ Cavity Every 3 Hours Inprocess Inprocess Inspection Hold and Report QA

2 Wet - Weight Quality Control Model Table (SSP-QA-003-036) Weight Check Daily Report (TFM-QA-028) Mgr.

& Limit Sample

7 Drying Drying Room 1 Quantity Temperature Follow การอบโฟมชิ้นงาน (TWI-PDA-010) Visual Check All Cart - Tag Number (TFM-PDA-020)

Timer Follow มาตรฐานการอบชิ้นงาน (TST-PDA-002), Temp Gauge All Drying Room Every Hour Temperature Record (TFM-PDA-023) Notify PDA

o

(60-80 C.) , (8-12 Hours) Timer All Cart Everyday Drying Record (TFM-PDA-022)

8 Inprocess Inspection

(After Drying) - Weight Scale 1 Appearance Follow Production Inprocess Inspection (TPR-QA-002 ) Visual Check Every 3 Hours Inprocess inspection daily report

Hold and Report QA

- C/F, Taper gauge 2 Wet - Weight Inspection Standard Part No.49401-A0010-A Weight Check 1 Pcs./ Cavity 1 time/Shift (TFM-QA-028)

Mgr.

- Mold mark 3 Dimension Taper gauge & Inprocess Inspection Sheet

9 Finishing & Packing - Cutter 1 Quantity Follow Method contain part foam Visual Check Every Every Lot ใบส่งมอบสินค ้าส าเร็จรูป

Packaging

2 Apperance การบรรจุโฟมชิ้นงาน(TWI-PDA-011) (TFM-AM-029) Notify PDA

3 Label and Packing Std. Approved by Customer WI Finishing & Q-Point

10 Storage ( Finish Goods ) Hand Lift 1 Quantity FIFO System Follow Raw Material and Finish Goods Stock Control Visual Check Every Every Lot Layout Board

Packaging Notify AM Mgr.

การควบคุมสินค ้าคงคลังและสินค ้าส าเร็จรูป (TPR-AM-009)

11 Outgoing Inspection 1 Appearance Follow WI outgoing inspection Visual Check Every pcs.

Hold and Report

2 Dimension (TPR-QA-003) Taper gauge AQL 4.0 % Every Lot DATA OUTGOING SHEET QA Mgr.

3 Weight Inspection Standard Weight Check AQL 4.0 %

12 Delivery Hand Lift 1 Quantity Counting Check Invoice and Daily Delivery Plan Report

Follow Delivery Procedure (TPR-AM-010) Visual Check Every Box Every Lot Notify AM Mgr.

Delivery Plan (TFM-AM-042)

Symbol : = CC point = SC point