Page 18 - PPAP submission requirements (PPAP check sheet)

P. 18

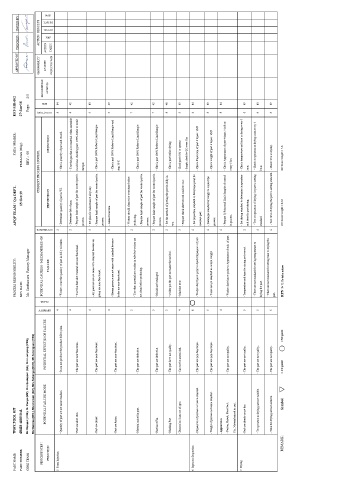

PART NAME: TRAY,TOOL KIT PROCESS RESPONSIBILITY: APQP TEAM / QA DEPT. FMEA NUMBER: EST-MR-002 APPROVED BY CHECKED ISSUED BY

PART NUMBER: 49401-A0010-A KEY DATE: 15-Oct-19 FMEA Date (Orig.): 27-Jan-18

CORE TEAM: Mr.Worajuk (PDE), Mr Panya (MP), Mrs.Sudaporn (QA), Mrs.Lamyong (PDA), Mr. Janthaworn Factory Manager REV.: 00 Page: 2/3

Ms.Wannee (DEL), Ms.Uraiwan (AM), Mrs.Sukanya (DCO), Mr.Tanongsak (ENG)

PROCESS STEP / POTENTIAL FAILURE MODE POTENTIAL EFFECT(S) OF FAILURE POTENTIAL CAUSE(S) / MECHANISM(S) OF CURRENT PROCESS CONTROL RECOMMENDED RESPONSIBILITY ACTION RESULTS

& TARGET

FUNCTION SEVERITY CLASS FAILURE OCCURANCE PREVENTION DETECTION DETECTION RPN ACTION(S) COMPLETION DATE ACTION SEV. OCCUR. DETECT. RPN

TAKEN

5. Foam Injection 4 2 8 64

- Quantity of part are not same standard. - It can not produce the product follow plan. - Worker count the quantity of part in dolly mistaken. - Determine quantity of part in WI. - Check quantity of part and record.

4 2 - Determine life of gun. - Test the gun that shot material when assemble 6 48

- Part are short shot. - The part are non-functional. - The Gun that shot material are non-functional. - Prepare limit sample of part for control part in mould and checking part 100% Refer to Limit

process. Sample

4 3 - Set plan for maintenance air pump. 5 60

- Air pressure are not same with standard because air

- Part are shirnk - The part are non-functional. - Prepare limit sample of part for control part in - Check part 100% Refer to Limit Sample

pump are non-functional.

process.

4 2 - Alarm Detection. 5 40

- Stream pressure are not same with standard because - Check part 100% Refer to Limit Sample and

- Part are fusion. - The part are non-functional.

boiler are non-functional. stop M/C

- Worker should clean tube everytime before

3 2 7 42

- Material mixed in part. - The part are defective. - The other material are residue in tube but worker are producing. - Check part 100% Refer to Limit Sample

not clean before producing. - Prepare limit sample of part for control part in

process.

3 2 - Prepare limit sample of part for control part in 7 42

- Part have Fin - The part are defective. - Mould are breakaged - Check part 100% Refer to Limit Sample

process.

3 2 - Set the method of putting the part in dolly in 8 48

- Marking Part - The part have not quality. - worker put the part not same the method. - Check part before drying.

WI.

- Dimension foam out of spec. - Can not be assembled. 4 - Machine error 3 - Check part 100% by operator 5 60

- Prepare check sheet record conditon m/c

- Sample check by QC every 3 hr.

6. Inprocess Inspection 8 2 - Set inspection standard to determine point for 4 64

- Dimension of part are not same standard. - The part are non-functional. - Worker don't know point to check Dimension of part. - Check dimension of part 4 times / shift

measure part.

5 2 - Determine standard of weight to control the 6 60

- Weight of part are not same standard. - The part are non-functional. - There are not standard to control weight. - Check weight of part 4 times / shift

process.

- Appearance 4 2 8 64

- Fusion, Shirnk, Short Sort, - The part are not quality. - Worker don't know point to Appearance check of part. - Prepare Q-Point and Limit Sample of control - Check Appearance of part 4 times / shift or

in process. every 3 hrs.

Fin, Material mixed in part.

7. Drying - Set drying standard to determine temperature - Check temperature and time to drying every 1

- Part are shrank or not dry. - The part are not quality. 5 - Temperature and time for drying not correct. 2 6 60

and time for part drying. hour.

- There are not standard for setting temperature to - Test temperature of drying the part to setting - Check temperature at drying room every 1

- Temperature at drying part not suitable. - The part are not quality. 5 2 6 60

drying the part. standard. hour.

- There are not standard for setting time to drying the

- Time for drying part not suitable. - The part are not quality. 5 2 - Test time of drying the part to setting standard. - Check time everyday. 6 60

part.

REMARK: Symbol = CC point = SC point RPN > 72 To take action CC Score weight = 9-10 SC Score weight = 7-8