Page 19 - PPAP submission requirements (PPAP check sheet)

P. 19

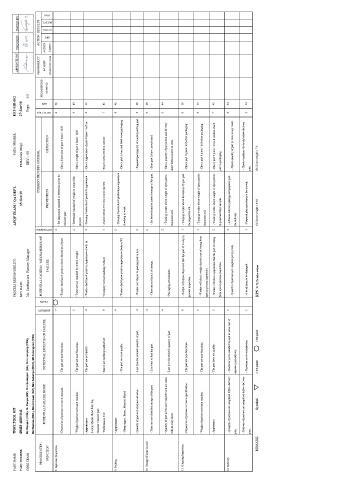

PART NAME: TRAY,TOOL KIT PROCESS RESPONSIBILITY: APQP TEAM / QA DEPT. FMEA NUMBER: EST-MR-002 APPROVED BY CHECKED ISSUED BY

PART NUMBER: 49401-A0010-A KEY DATE: 15-Oct-19 FMEA Date (Orig.): 27-Jan-18

CORE TEAM: Mr.Worajuk (PDE), Mr Panya (MP), Mrs.Sudaporn (QA), Mrs.Lamyong (PDA), Mr. Janthaworn Factory Manager REV.: 00 Page: 3/3

Ms.Wannee (DEL), Ms.Uraiwan (AM), Mrs.Sukanya (DCO), Mr.Tanongsak (ENG)

ACTION RESULTS

PROCESS STEP / POTENTIAL FAILURE MODE POTENTIAL EFFECT(S) OF FAILURE POTENTIAL CAUSE(S) / MECHANISM(S) OF CURRENT PROCESS CONTROL RECOMMENDED RESPONSIBILITY ACTION

& TARGET

FUNCTION SEVERITY CLASS FAILURE OCCURANCE PREVENTION DETECTION DETECTION RPN ACTION(S) COMPLETION DATE TAKEN SEV. OCCUR. DETECT. RPN

8. Inprocess Inspection 7 2 - Set inspection standard to determine point for 4 56

- Dimension of part are not same standard. - The part are non-functional. - Worker don't know point to check dimention of part. - Check dimension of part 4 times / shift

measure part.

5 2 - Determine standard of weight to control the 6 60

- Weight of part are not same standard. - The part are non-functional. - There are not standard to control weight. - Check weight of part 4 times / shift

process.

- Appearance - The part are not quality. 4 - Worker don't know point to Appearance check in 2 - Training worker about product's appearance - Check Appearance of part 4 times / shift or 4 32

Fusion, Shirnk, Short Sort, Fin,

Material mixed in part.

- Performance Test - Result not mathing method test 9 - Company test not mathing method 1 - Attached method every time at submit part test - Request method test from customer 7 63

9. Packing - Appearance 4 2 - Training worker about productions appearance 6 48

- The part have not quality. - Worker don't know point to appearance check in WI - Check part in box and label when packaging.

- Sharp egges , Burrs , Material Mixed checking in work.

- Quantity of part and label are not same. - Lost time for recheck quantity of part. 4 - Worker don't know to packing part in box. 2 - Prepared packing std. of control packing part. 6 48

10. Storage (Finish Goods) 4 2 6 48

- There are not identified storage of the part. - Lost time to find the part. - There are not layout of storage. - Set layout board to control storage of the part. - Store part follow layout board.

4 2 8 64

- Quantity of part in box not complete and not same - Lost time for recheck quantity of part. - Packaging are mistaken. - Training worker about weight of spec part to - Check quantity of part in box and delivery

with delivery sheet. inspection std. sheet before receive in store.

11. Outgoing Inspection 6 - Worker will check dimention that the part of wrong in 1 - Training worker about dimention of spec part 6 36

- Dimension of part are not same specification. - The part are non-functional. - Check part 8 piece/ lot before packaging.

process inspection. for inspection std..

5 1 - Training worker about weight of spec part for 6 30

- Weight of part are not same standard. - The part are non-functional. - Worker will check weight that the part of wrong from - Check part 8 piece / lot before packaging.

spec in process inspection. inspection std.

- Appearance - The part have not quality. 3 - Worker will check appearance that the part of wrong 2 - Training worker about weight of spec part for - Check part 8 piece / lot and random check 7 42

from spec in process inspection. Q-point and limit sample. part in packaging.

12. Delivery - Quantity of part are not completed follow delivery - Customer not to satisfaction and to raise cost of 3 3 - Advance delivery planing and prepares part 6 54

plan. repeated part delivery. - Quantity of part are not complete pat in stock. for delivery. - Check quantity of part in stock every week.

- Delivery of part are not completed follow delivery - Customer not to satisfaction. 3 - A truck from to be damaged. 1 - Prepared plan maintenance for a truck. - Check condition of a truck before delivery 8 24

plan. part.

REMARK: Symbol = CC point = SC point RPN > 72 To take action CC Score weight = 9-10 SC Score weight = 7-8