Page 21 - PPAP submission requirements (PPAP check sheet)

P. 21

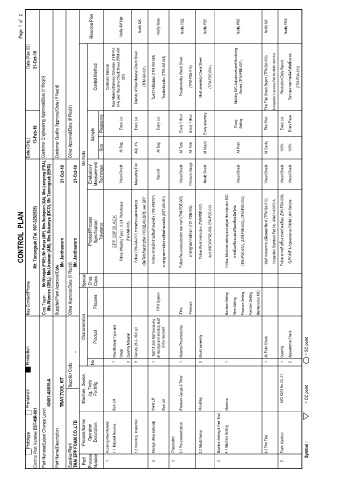

CONTROL PLAN Page 1 of 2

Prototype Pre-launch Production Key Contact/Phone Date (Orig.) Date (Rev.02)

Control Plan Number EST-MR-001 Mr. Tanongsak (Tel. 097-3282926) 13-Feb-18 21-Oct-19

Part Number/Latest Change Level Core Team : Mr.Worajuk (PDE), Mr Panya (MP), Mrs.Sudaporn (QA), Mrs.Lamyong (PDA), Customer Engineering Approval/Date (If Req'd)

49401-A0010-A Ms.Wannee (DEL), Ms.Uraiwan (AM), Mrs.Sukanya (DCO), Mr.Tanongsak (ENG)

Part Name/Description Supplier/Plant Approval/Date Customer Quality Approval/Date (If Req'd)

TRAY,TOOL KIT Mr. Janthaworn 21-Oct-19

Supplier/Plant Supplier Code Other Approval/Date (If Req'd) Other Approval/Date (If Req'd)

THAI EPP FOAM CO.,LTD - Mr. Janthaworn 21-Oct-19

Part/ Process Name/ Machine, Device, Characteristics Special Methods

Process Operation Jig, Tools No. Char. Product/Process Evaluation/ Sample Reaction Plan

Number Description For Mfg. Product Process Class. Specification/ Measurement Control Method

Tolerance Technique Size Frequency

1 Incoming Raw Material Certificate Material

1.1 Material Receive Fork Lift 1 Raw Material Type and EPP 30P BLACK Raw Material Delivery Schedule (TFM-PU-

014) and Receive Check Sheet (TFM-AM-

Grade Follow Shipping Type 1, 2,3,4 Warehouse Visual Check All Bag Every Lot Notify AM Mgr.

028)

2 Quantity Material (TWI-AM-005)

1.2 Incoming Inspection 3 Density 24.2- 30.0 g/l Follow (TWI-QA-017) การตรวจและทดสอบ Measuring Tool AQL 4% Every Lot Density of Raw Material Check Sheet

Notify QA

เม็ดโฟมรับเข ้าชนิด PIOCELAN, EPE และ EPP (TFM-QA-001)

2 Storage (Raw material) Hand Lift 1 Mat'l & Sub Mat'l receiving Follow การเบิกจ่ายสินค ้าคงคลัง (TWI-AM-007) ใบตรวจนับของ (TFM-AM-028)

in storage and sending mat'l FIFO System Record All Bag Every Lot Notify Store

Fork Lift to the next part. มาตรฐานการจัดวางสินค ้าคงคลัง (SST-AM-001) ใบเบิกวัตถุดิบ (TFM-AM-031)

3 Preparation

3.1 Pre-pressurization Pressure Gauge & Timer 1 Material Pre-pressurize -Time Follow Pre-pressurizetion raw mat't (TWI-PDE-005) Visual Check All Tank Every 1 Hour Pre-pressurize Check Sheet Notify PDE

-Pressure มาตรฐานการอัดยา (TST-PDE-002) Pressure Gauge All Tank Every 1 Hour (TFM-PDE-016)

3.2 Mould Setup Moulding 2 Mould assembly Follow Work Instruction (TWI-PDE-001) Mold assembly Check Sheet

Mould Check All Mould Every assembly Notify PDE

And WI EWI-PDE-003, EWI-PDE-013 (TFM-PDE-004 )

4 Machine Setting & First Trial

4.1 Machine Setting Machine 1 Machine Setting Follow Machine setting and adjust the injection M/C.

Time Setting การตั้งเครื่องและปรับเครื่องฉีดโฟม Every Molding M/C Adjustment and Monitoring

Visual Check All Point Notify PDE

Pressure Setting (TWI-PDE-002), (EWI-PDE-002), (TFM-PDE-002) Setting Record (TFM-PDE-001)

Function Setting

Maintenance M/C

4.2 First Trial 1 All Point Check ข ้อก าหนดการเปลี่ยนแม่พิมพ์ (TFM-QA-012) Visual Check All Cavity First Shot First Trial Check Report (TFM-QA-013) Notify QA

Inspection Standard Part No. 49401-A0010-A & Inspection Inprocess Part No.49401-A0010-A

5 Foam Injection M/C K813 No.20, 21 1 Quantity Follow การเก็บชิ้นงานหน้าเครื่อง (EWI-PDA-006) Visual Check 100% Every Lot Production Daily Report

Notify PDA

2 Appearance Check Q-POINT & Appearance Critirial Limit Sample Visual Check 100% Every Piece ใบรายงานการผลิตโฟมชิ้นงาน

(TFM-PDA-013)

Symbol : = CC point = SC point