Page 292 - Installation Training Binder FIT1-3

P. 292

APPLICATION BRIEF 1001

Impact of Non-Compliance with UPS Flooded Lead Acid Batteries

Impact of Non-Compliance with UPS Flooded Lead Acid Batteries

Introduction: Recommendations:

Lead acid batteries are classied as hazardous due to the corrosive Avoid the potential impact of non-compliance by doing the

sulfuric acid electrolyte and lead content. State and local re following:

codes address the Storage of Lead Acid Batteries and typically 1. Specify UL Listed Spill Containment for ALL ooded lead acid

require spill containment and neutralization when the total battery applications (particularly when electrolyte volume

volume of the battery system is 50 gallons or more. These codes exceeds the 50 gallon threshold imposed by most

require “an approved method and materials control and municipalities). Many cities and local municipalities require

neutralization… in the event of an electrolyte spill.” construction materials to be UL Listed when available.

Understanding the specic codes enables sound 2. Standardize on spill containment specications to include UL

recommendations, specications and purchase decisions. Listing. Incorporate with backup power system specications to

ensure inclusion throughout the project supply chain and

Problem to solve: lifecycle.

3. Use spill containment for systems that have less than 50 gallons

Codes vary from city to city as well as re inspector understanding as good practice in hazmat management.

and knowledge of battery systems. It is safe to say that ALL cities

and local municipalities require spill containment and

neutralization for ooded lead acid batteries. What qualies as “an “I always specify spill containment for ooded lead-acid

approved” method and materials? battery systems!”

- Colorado Electrical Engineer

IFC Sect. 608 – Flooded Battery Systems > 50 gal.

608.4 Spill control and neutralization. An approved method and Benets:

materials for the control and neutralization of a spill of Benets realized from initial installation of spill containment for

electrolyte shall be provided. The method and materials shall be ooded lead-acid battery systems are labor savings and on-time

capable of controlling and neutralizing a spill from the largest projects.

lead-acid battery to a pH between 7.0 and 9.0. • Cost avoidance

• Meet code compliance

Impact: • Safe environment

The cost of a retrot is typically 4 to 5 times the cost of an initial

“Non-approved” systems or not installing spill containment at all, installation as shown in Table 1.

will likely result in heavy consequences. In most cases, the

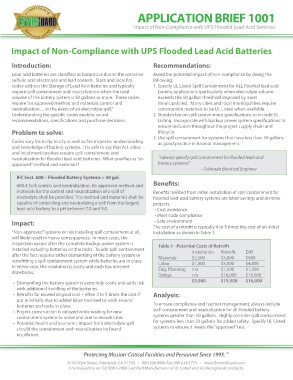

inspection occurs after the complete backup power system is Table 1 - Potential Costs of Retrot

installed including batteries on the racks. To add spill containment Installation Retrot Di.

after the fact requires either dismantling of the battery system or Materials $2,500 $3,000 $500

retrotting a spill containment system while batteries are in place. Labor $1,000 $5,000 $4,000

In either case, the resolution is costly and each has inherent Eng. Planning n/a $1,500 $1,500

drawbacks.

Delays n/a $10,000 $10,000

• Dismantling the battery system is extremely costly and adds risk $3,500 $19,500 $16,000

with additional handling of the batteries.

• Retrofits far exceed original cost – often 3 to 5 times the cost if Analysis:

put in initially due to added labor involved to work around

batteries and racks in place. To ensure compliance and hazmat management, always include

• Project construction is delayed while waiting for new spill containment and neutralization for all ooded battery

containment system to arrive and due to rework time. systems greater than 50 gallons. Highly consider spill containment

• Potential health and economic impact from electrolyte spill for systems less than 50 gallons for added safety. Specify UL Listed

should the containment and neutralization be found systems to ensure it meets the “approved” test.

insucient.