Page 294 - Installation Training Binder FIT1-3

P. 294

APPLICATION BRIEF 1003

Avoiding the hidden costs of compliance with VRLA Cabinets

Avoiding the hidden costs of compliance with VRLA Cabinets

Introduction: some cabinet installations leading to potentially substandard spill

containment.

Installing spill containment based only on code compliance for

VRLA battery cabinets could cost 5 to 7 times the amount of labor Depending on the cabinet and weight, it may be possible to hoist

due to other unforeseen approvers requiring containment after the cabinet suciently, with proper rigging, to slide the spill

batteries are installed and on-line. containment under the cabinet. A retrot solution that results in

100% liquid tight and passive neutralization is desirable. The best

The Diculty in Approval: solutions would be to install spill containment with all VRLA

battery systems. Typical foot prints for VRLA battery systems are

IFC 609 states “An approved manual method and materials for small in size so spill containment is most economical.

neutralization of a release of electrolyte shall be provided. “ The

code does not specify the requirement for control or containment. Benets:

Companies adopt the code, mainly, as primary decision criteria

when choosing whether to use spill containment or not. When Shown in Table 1 is a case where the retrot costs are over 3 times

containment is NOT used, some companies may nd that the the cost of an initial installation. Not included in the cost analysis

installation is NOT acceptable based on the decision of the code is the cost of project delays, potential rigging to hoist the cabinet

enforcer or inspector. Even when the re inspector signs o, there and added spill protection.

are other approvers involved. These could include building

owners or managers, commercial insurers, OSHA or even the

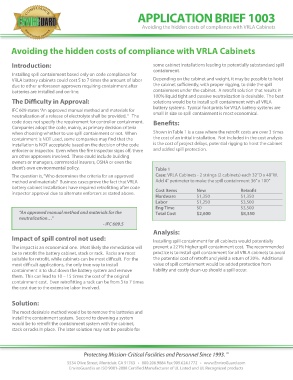

client’s own environmental policy. Table 1

The question is, “Who determines the criteria for an approved Case: VRLA Cabinets - 2 strings (2 cabinets) each 32”D x 48”W.

method and materials? Business cases prove the fact that VRLA Add 4” perimeter to make the spill containment 36” x 100”

battery cabinet installations have required retrotting after code Cost Items New Retrot

inspector approval due to alternate enforcers as stated above.

Hardware $1,350 $1,350

Labor $1,250 $3,500

Eng Time $0 $3,500

“An approved manual method and materials for the Total Cost $2,600 $8,350

neutralization…”

- IFC 609.5

Analysis:

Impact of spill control not used: Installing spill containment for all cabinets would potentially

The impact is an economical one. Most likely the remediation will prevent a 221% higher spill containment cost. The recommended

be to retrot the battery cabinet, stack or rack. Racks are most practice is to install spill containment for all VRLA cabinets to avoid

suitable for retrot, while cabinets can be most dicult. For the the potential cost of retrot and yield a return of 20%. Additional

most dicult applications, the only true way to install value of spill containment would be added protection from

containment is to shut down the battery system and remove liability and costly clean-up should a spill occur.

them. This can lead to 10 – 15 times the cost of the original

containment cost. Even retrotting a rack can be from 3 to 7 times

the cost due to the extensive labor involved.

Solution:

The most desirable method would be to remove the batteries and

install the containment system. Second to downing a system

would be to retrot the containment system with the cabinet,

stack or racks in place. The later solution may not be possible for