Page 325 - Installation Training Binder FIT1-3

P. 325

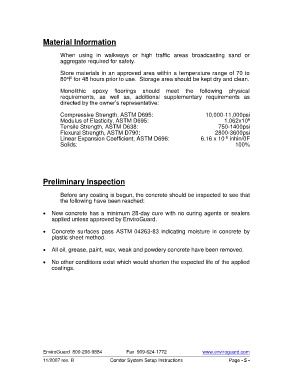

Material Information

When using in walkways or high traffic areas broadcasting sand or

aggregate required for safety.

Store materials in an approved area within a temperature range of 70 to

80 F for 48 hours prior to use. Storage area should be kept dry and clean.

o

Monolithic epoxy floorings should meet the following physical

requirements, as well as, additional supplementary requirements as

directed by the owner’s representative:

Compressive Strength, ASTM D695: 10,000-11,000psi

6

Modulus of Elasticity, ASTM D695: 1.062x10

Tensile Strength, ASTM D638: 750-1400psi

Flexural Strength, ASTM D790: 2800-3600psi

-6

Linear Expansion Coefficient, ASTM D696: 6.16 x 10 inhin/0F

Solids: 100%

Preliminary Inspection

Before any coating is begun, the concrete should be inspected to see that

the following have been reached:

• New concrete has a minimum 28-day cure with no curing agents or sealers

applied unless approved by EnviroGuard.

• Concrete surfaces pass ASTM 04263-83 indicating moisture in concrete by

plastic sheet method.

• All oil, grease, paint, wax, weak and powdery concrete have been removed.

• No other conditions exist which would shorten the expected life of the applied

coatings.

EnviroGuard 800-206-9884 Fax 909-624-1772 www.enviroguard.com

11/2007 rev. B Condor System Setup Instructions Page - 5 -