Page 150 - Binder

P. 150

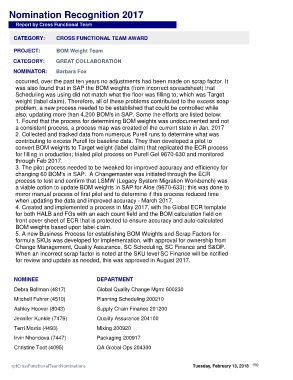

Nomination Recognition 2017

Report by Cross Functional Team

CATEGORY: CROSS FUNCTIONAL TEAM AWARD

PROJECT: BOM Weight Team

CATEGORY: GREAT COLLABORATION

NOMINATOR: Barbara Fox

occurred, over the past ten years no adjustments had been made on scrap factor. It

was also found that in SAP the BOM weights (from incorrect spreadsheet) that

Scheduling was using did not match what the floor was filling to; which was Target

weight (label claim). Therefore, all of these problems contributed to the excess soap

problem, a new process needed to be established that could be controlled while

also, updating more than 4,200 BOM's in SAP. Some the efforts are listed below:

1. Found that the process for determining BOM weights was undocumented and not

a consistent process, a process map was created of the current state in Jan. 2017

2. Collected and tracked data from numerous Purell runs to determine what was

contributing to excess Purell for baseline data. They then developed a pilot to

convert BOM weights to Target weight (label claim) that replicated the ECR process

for filling in production; trialed pilot process on Purell Gel 9670-630 and monitored

through Feb 2017.

3. The pilot process needed to be tweaked for improved accuracy and efficiency for

changing 60 BOM's in SAP. A Changemaster was initiated through the ECR

process to test and confirm that LSMW (Legacy System Migration Workbench) was

a viable option to update BOM weights in SAP for Aloe (9670-633); this was done to

mirror manual process of first pilot and to determine if this process reduced time

when updating the data and improved accuracy - March 2017.

4. Created and implemented a process in May 2017, with the Global ECR template

for both HALB and FGs with an each count field and the BOM calculation field on

front cover sheet of ECR that is protected to ensure accuracy and auto-calculated

BOM weights based upon label claim.

5. A new Business Process for establishing BOM Weights and Scrap Factors for

formula SKUs was developed for implementation, with approval for ownership from

Change Management, Quality Assurance, SC Scheduling, SC Finance and S&OP.

When an incorrect scrap factor is noted at the SKU level SC Finance will be notified

for review and update as needed, this was approved in August 2017.

NOMINEE DEPARTMENT

Debra Bollman (4817) Global Quality Change Mgmt 600230

Mitchell Fuhrer (4510) Planning Scheduling 200210

Ashley Hoover (8043) Supply Chain Finance 201200

Jennifer Kunkle (7476) Quality Assurance 204100

Terri Morris (4493) Mixing 200920

Irvin Nhondova (7447) Packaging 200917

Christine Toot (4095) QA Global Ops 204300

rptCrossFunctionalTeamNominations Tuesday, February 13, 2018 150