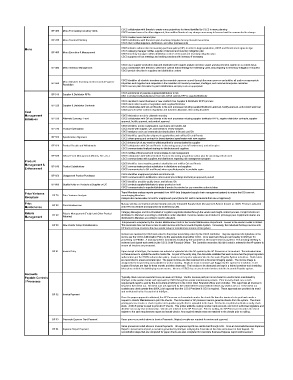

Page 400 - Board Member Onboardin August 2019

P. 400

CSCS collaborates with Brands to create menu projections for items identified by CSCS in menu planning

BP 460 Menu Forecasting Including Yields

CSCS reviews forecast to affirm alignment, then notifies Brands of any changes necessary to forecast and the reasons for the change

CSCS creates menu demand plan

BP 470 Menu Demand Planning CSCS collaborates with Brands to plan inventory mitigation for any relevant menu items

CSCS then notifies suppliers, distributors, and other business units

Menu CSCS initiates authorization for inventory purchase policy (AIP). In order to begin production, CSCS and Brands must agree to sign

CSCS category manager notifies supplier of demand and inventory mitigation plan

BP 480 Menu Execution & Management

CSCS inventory manager notifies distribution centers of demand and inventory mitigation plan

CSCS supports roll out meetings and training sessions with inventory if necessary

CSCS uses supplier production data and distributor order data to analyze inventory usage and placement in system on a periodic basis

BP 490 Menu Inventory Management CSCS collaborates with Brands to determine optimal Brand strategy for minimizing costs, and preparing for inventory mitigation if required

CSCS provide direction to suppliers and distribution centers

CSCS identifies all obsolete inventory and incremental expenses caused through the menu process and notifies all parties as appropriate

Menu Obsolete Inventory and Incremental Expense

BP 500 All parties work together and cooperate in the resolution of inventory excesses, shortages, and incremental expense resolution

Resolution

CSCS execute plan determine by joint collaboration and pay costs as appropriate

CSCS submits list of possible suppliers/distributors to QA

BP 510 Supplier & Distributor RFPs

After receiving feedback/guidance from QA, CSCS submits RFP to supplier/distributor

CSCS decides to award business or new contract from Supplier & Distributor RFP's process

CSCS starts initial rounds of negotiation with supplier/distributor

BP 520 Supplier & Distributor Contracts

CSCS collaborates with QA and Brands in the next processes including supplier/distributor approval, facility approval, and product approval

CSCS pursue further contract negotiation and business allocation, then notify all parties

Cost

Management CSCS determines need for alternate sourcing

Initiatives BP 530 Alternate Sourcing - Food CSCS collaborates with QA and Brands in the next processes including supplier distributor RFP's, supplier distributor contracts, supplier

approval, facility approval, and product approval

CSCS identifies product optimization opportunity and notifies QA

BP 540 Product Optimization CSCS works with supplier, QA, and Brands to review samples

CSCS analyzes costs and communicates implications to Brands and QA

CSCS identifies specification alignment opportunities and notifies QA and Brands

BP 550 Specification Alignment

CSCS obtain pricing and contract for Brand standard specification with new supplier

CSCS informs QA of any recall or withdrawal that is communicated by supplier

BP 620 Product Recalls and Withdrawals CSCS collaborates with QA and Brands in discussing scope, level of involvement, and action plan

CSCS communicates finalized strategy to distributors and suppliers

CSCS notifies critical event and communicates to risk management

BP 630 Critical Event Management (Storms, Fire, etc.) CSCS collaborates with Critical Incident Team in discussing preparatory action plan for upcoming critical event

CSCS communicates with suppliers and distributors regarding risk management program

Product

Management & BP 640 Product Substitutions CSCS identifies issue requiring product substitution and notifies QA and Brands

CSCS communicates product substitution to distributors and suppliers

Enforcement CSCS communicates to QA and Brands when specified product is available again

CSCS identifies unapproved product and informs QA

BP 650 Unapproved Product Purchases

CSCS communicates to distributors enforcement proceedings and bring in approved product

CSCS identifies possible quality issues and informs QA

BP 660 Quality Holds on Products at Supplier or DC CSCS contacts supplier/distributor to place product on hold

CSCS communicates to supplier/distributor if product is rejected or any corrective action is taken

Price Variance BP 20 Price Variance Analysis Team Members analyze reports generated from HAVI data (integrated supply chain management system) to ensure that DCs are not

overcharging Members.

Recapture Analysts also review sales to look for unapproved spend (items DC sold to restaurants that are not approved)

Price BP 30 Price Maintenance Manage pricing and maintain pricing integrity using the Integrated Supply Chain Management System (known as HAVI). Pricing is uploaded

Maintenance onto HAVI by vendors and approved via workflow by CMs.

Rebate BP 40 Rebate Management (Freight and Other Product Category Managers and Vice President of Logistics negotiate rebates through the vendor and freight contract process. Freight rebates are

distributed to Members according to distribution center allocation. Revenue rebates are included in patronage pool. Equipment rebates are

Management Rebates) distributed to Members according to vendor allocation.

This process is completed by the Vendor Maintenance Clerk in the Vendor Maintenance Department. Access to the vendor master is limited.

BP 50 New Vendor Setup & Maintenance This Associate does not have access to enter invoices into the Accounts Payable System. Conversely, the individual that keys invoices into

AP does not have access to the new vendor setup or maintenance screens of the system

Invoices are received by CSCS and coded to the proper accounting codes by the CSCS Controller. They are approved via signature on the

invoice per the CSCS Authorization Policy by the appropriate level within CSCS. Once approved, they are sent weekly to InfoSync for

processing via FEDEX. A tracking sheet is maintained at CSCS by the Controller of all invoices sent for payment. This tracking sheeting is

reviewed and signed each week by the CSCS Chief Financial Officer. The Controller reconciles this list to what is entered in the AP system to

ensure all invoices are processed.

BP 51 Invoice Entry Upon receipt at InfoSync, the invoices are entered or uploaded into the AP system by the AP Processor or Accountant. This individual does

not have access to update the vendor master file. As part of the entry step, this Associate validates that each invoice has the proper signature

authorization per the CSCS authorization policy. Invoices are keyed or uploaded into the Accounts Payable System in batches. Batch totals

are reconciled to ensure accurate input. The paper invoices are then scanned into a document imaging system. The invoice image is

assigned to the keyed entry and available for on-line viewing. Duplicate invoice numbers get flagged by the system for resolution. Hard

copies of invoices are kept for three months and then destroyed. The invoices to be destroyed are kept in a locked container and shredding

takes place outside the building by secure means. No one at CSCS has access to enter invoices into the Accounts Payable system.

Accounts

Payable Controls Typically check runs are executed once per week on Fridays. Vendor invoices paid per run are based on vendor terms maintained by

/ Processes InfoSync in the vendor master and approved by CSCS through the vendor maintenance process. Prior to every check run, a cash

requirements report is sent by the Accountant at InfoSync to the CSCS Chief Financial Officer and Controller. This report lists all invoices to

be paid in that check run. All check runs are approved by the CSCS Chief Financial Officer before any checks are cut. If the check run

contains any check greater than $50K, joint approval from the CSCS President & CEO is required. These approvals are provided via email

and maintained by the Accountant at InfoSync.

BP 52 Invoice Payment

Once the proper approval is obtained, the AP Processor or Accountant creates the check file from the invoices to be paid and emails a

request to Vendor Maintenance to print the checks. The Accountant or AP processor cannot generate checks from the system. The check

printing process creates a check register and a positive pay file that is uploaded to the bank. All checks are printed on blank security check

stock. A MICR printer is used to print all AP checks. This printer adds the routing number, bank account, and CSCS authorized signature and

all other necessary check information. Checks are returned to the AP Processor. Prior to mailing, the AP Processor reconciles the check

register to the cash requirements report and actual checks. Any required attachments are matched to the checks prior to mailing.

BP 53 Corporate Expense Card Payment Same process as noted above in Invoice Payments. Original receipts are required for review and approval.

Same process as noted above in Invoice Payments. All expense reports are reimbursed through ACH. Once an Associate Business Expense

BP 54 Expense Report Payment Report is processed and paid, an email is generated by InfoSync notifying the Associate of the date and amount of their deposit. All

reconciliation steps that are completed for paper checks are also completed for Associate Business Expense report reimbursement.