Page 29 - UL_Report On_Part 1

P. 29

21 IITGN-UL/Façade 22 IITGN-UL/Façade

(i) Glass

The common material under performance evaluation for

all tests is glass. Test 1 involved local market glass whereas (ii) Aluminium Composite Panel (ACP)

tests 2, 3 and 4 involved standard glass. Standard glass was

Saint Gobain toughened glass of size 1200 x 400mm and 6 Aluminium composite panel is composed of

mm thickness fixed to the aluminium cladding framework polyethylene core laminated and sandwiched

through pressure tapes and silicon sealant as binder gel. between two fine aluminium sheets. ALU DÉCOR AL

Technical specifications of glass under testing are as 45 ACP sheets are used in combination with local

follows: 58 x 64mm. Aluminium Section Frame ( Center) glass for test 1 whereas ACP sheets are combined

with Saint gobain toughened glass for test 2.

Fire Stop Material

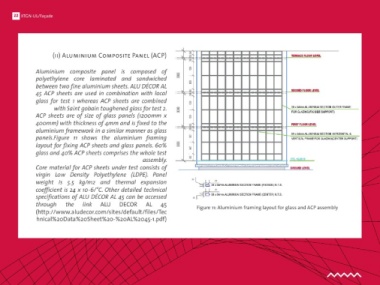

• Thermal shock resistance: Upto 250°C ACP sheets are of size of glass panels (1200mm x

• Mechanical strength: four to five times stronger 400mm) with thickness of 4mm and is fixed to the

aluminium framework in a similar manner as glass

than annealed glass 6mm Glass Deck Slab panels.Figure 11 shows the aluminium framing

• Tensile strength: 65 MPa layout for fixing ACP sheets and glass panels. 60%

• Bending strength: 120-200 N/mm2 150 glass and 40% ACP sheets comprises the whole test

• Surface compression: >95 MPa assembly.

• Design stress for architectural purposes: 50 MPa Silicon Core material for ACP sheets under test consists of

• Fragmentation: Small round crystals Hollow Space virgin Low Density Polyethylene (LDPE). Panel

• Conducive for processing 6MM X 6MM Pressure Tap weight is 5.5 kg/m2 and thermal expansion

• Cannot be cut after toughening coefficient is 24 x 10-6/°C. Other detailed technical

Figure 10: Typical installation layout of a glass panel to aluminium framework

specifications of ALU DÉCOR AL 45 can be accessed

Glass panels are fixed to aluminium cladding framework through the link ALU DECOR AL 45 Figure 11: Aluminium framing layout for glass and ACP assembly

made of rectangular tube of size 58mm x 64mm as (http://www.aludecor.com/sites/default/files/Tec

horizontal and vertical center glazing support and 38mm x hnical%20Data%20Sheet%20-%20AL%2045-1.pdf)

64mm as fixed size support. Glass panels are fixed with

aluminium framework through silicon structural glazing

sealant (Dow Corning brand) and through 6mm pressure

tape (Kotadiya brand). Figure 10shows typical installation

layout of a glass panel to aluminium framework.