Page 16 - AAS & AES & FES 01082016_Neat

P. 16

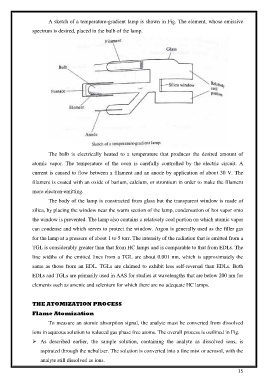

A sketch of a temperature-gradient lamp is shown in Fig. The element, whose emissive

spectrum is desired, placed in the bulb of the lamp.

The bulb is electrically heated to a temperature that produces the desired amount of

atomic vapor. The temperature of the oven is carefully controlled by the electric circuit. A

current is caused to flow between a filament and an anode by application of about 30 V. The

filament is coated with an oxide of barium, calcium, or strontium in order to make the filament

more electron-emitting.

The body of the lamp is constructed from glass but the transparent window is made of

silica, by placing the window near the warm section of the lamp, condensation of hot vapor onto

the window is prevented. The lamp also contains a relatively cool portion on which atomic vapor

can condense and which serves to protect the window. Argon is generally used as the filler gas

for the lamp at a pressure of about 1 to 5 torr. The intensity of the radiation that is emitted from a

TGL is considerably greater than that from HC lamps and is comparable to that from EDLs. The

line widths of the emitted lines from a TGL are about 0.001 nm, which is approximately the

same as those from an EDL. TGLs are claimed to exhibit less self-reversal than EDLs. Both

EDLs and TGLs are primarily used in AAS for studies at wavelengths that are below 200 nm for

elements such as arsenic and selenium for which there are no adequate HC lamps.

THE ATOMIZATION PROCESS

Flame Atomization

To measure an atomic absorption signal, the analyte must be converted from dissolved

ions in aqueous solution to reduced gas phase free atoms. The overall process is outlined in Fig.

As described earlier, the sample solution, containing the analyte as dissolved ions, is

aspirated through the nebulizer. The solution is converted into a fine mist or aerosol, with the

analyte still dissolved as ions.

15