Page 19 - AAS & AES & FES 01082016_Neat

P. 19

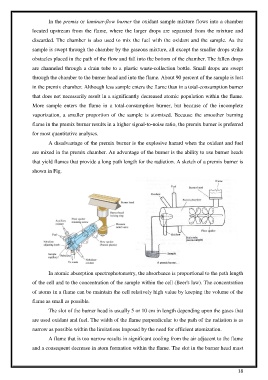

In the premix or laminar-flow burner the oxidant sample mixture flows into a chamber

located upstream from the flame, where the larger drops are separated from the mixture and

discarded. The chamber is also used to mix the fuel with the oxidant and the sample. As the

sample is swept through the chamber by the gaseous mixture, all except the smaller drops strike

obstacles placed in the path of the flow and fall into the bottom of the chamber. The fallen drops

are channeled through a drain tube to a plastic waste-collection bottle. Small drops are swept

through the chamber to the burner head and into the flame. About 90 percent of the sample is lost

in the premix chamber. Although less sample enters the flame than in a total-consumption burner

that does not necessarily result in a significantly decreased atomic population within the flame.

More sample enters the flame in a total-consumption burner, but because of the incomplete

vaporization, a smaller proportion of the sample is atomized. Because the smoother burning

flame in the premix burner results in a higher signal-to-noise ratio, the premix burner is preferred

for most quantitative analyses.

A disadvantage of the premix burner is the explosive hazard when the oxidant and fuel

are mixed in the premix chamber. An advantage of the burner is the ability to use burner heads

that yield flames that provide a long path length for the radiation. A sketch of a premix burner is

shown in Fig.

In atomic absorption spectrophotometry, the absorbance is proportional to the path length

of the cell and to the concentration of the sample within the cell (Beer's law). The concentration

of atoms in a flame can be maintain the cell relatively high value by keeping the volume of the

flame as small as possible.

The slot of the burner head is usually 5 or 10 cm in length depending upon the gases that

are used oxidant and fuel. The width of the flame perpendicular to the path of the radiation is as

narrow as possible within the limitations Imposed by the need for efficient atomization.

A flame that is too narrow results in significant cooling from the air adjacent to the flame

and a consequent decrease in atom formation within the flame. The slot in the burner head must

18