Page 22 - AAS & AES & FES 01082016_Neat

P. 22

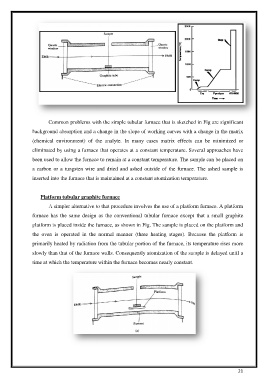

Common problems with the simple tubular ommon problems with the simple tubular furnace that is sketched in Figfurnace that is sketched in Fig are significant

C

b

background absorption and a change in the slope of workingackground absorption and a change in the slope of working curves with a change in the matrix curves with a change in the matrix

(chemical environment) of the analyte. Innvironment) of the analyte. In many cases matrix effects can be minimized or many cases matrix effects can be minimized or

e

eliminated by using a furnace thatliminated by using a furnace that operates at a constant temperature. Several approaches have operates at a constant temperature. Several approaches have

been used to allow the furnace to remain at a constant temperature. The sample can bthe furnace to remain at a constant temperature. The sample can bthe furnace to remain at a constant temperature. The sample can be placed on

a carbon or a tungsten wire and dried and ashed outside of the furnace. The ashedcarbon or a tungsten wire and dried and ashed outside of the furnace. The ashedcarbon or a tungsten wire and dried and ashed outside of the furnace. The ashed sample is

i inserted into the furnace that is maintained at a conserted into the furnace that is maintained at a constant atomization temperature.nstant atomization temperature.

P

Platform tubular graphite furnacelatform tubular graphite furnace

A

A simpler alternative to that simpler alternative to that procedure involves the use of a platform furnace.procedure involves the use of a platform furnace. A platform

f

furnace has the same design as the conventional tubular furnaceurnace has the same design as the conventional tubular furnace except that a small graphite except that a small graphite

p

platform is placed inside the furnace, as shown inlatform is placed inside the furnace, as shown in Fig. The sample is placed on the platform and . The sample is placed on the platform and

the oven is operated in the normal manner (three heating stages). Because the platform is normal manner (three heating stages). Because the platform is

primarily heated by radiation from the tubular portion of the furnace, its temperature rises moreby radiation from the tubular portion of the furnace, its temperature rises moreby radiation from the tubular portion of the furnace, its temperature rises more

slowly than that of the furnace walls. Consequently atomization of the salowly than that of the furnace walls. Consequently atomization of the sample ismple is delayed until a

s

time at which the temperature within the furnace becomes nearlyime at which the temperature within the furnace becomes nearly constant. constant.

t

21