Page 49 - Top Wheel Signature® Series

P. 49

SignatureSignature SeriesSeries

TOP WHEEL SignatureSignature ® SeriesSeries

Maintenance

Torque Plate and Electric Motor Replacement

Reinstall Motor Gearbox assembly

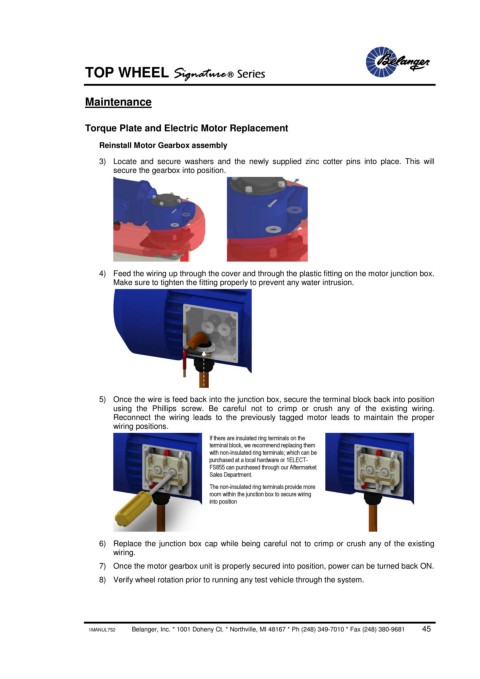

3) Locate and secure washers and the newly supplied zinc cotter pins into place. This will

secure the gearbox into position.

4) Feed the wiring up through the cover and through the plastic fitting on the motor junction box.

Make sure to tighten the fitting properly to prevent any water intrusion.

5) Once the wire is feed back into the junction box, secure the terminal block back into position

using the Phillips screw. Be careful not to crimp or crush any of the existing wiring.

Reconnect the wiring leads to the previously tagged motor leads to maintain the proper

wiring positions.

If there are insulated ring terminals on the

terminal block, we recommend replacing them

with non-insulated ring terminals; which can be

purchased at a local hardware or 1ELECT-

FS855 can purchased through our Aftermarket

Sales Department.

The non-insulated ring terminals provide more

room within the junction box to secure wiring

into position

6) Replace the junction box cap while being careful not to crimp or crush any of the existing

wiring.

7) Once the motor gearbox unit is properly secured into position, power can be turned back ON.

8) Verify wheel rotation prior to running any test vehicle through the system.

1MANUL752 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 45