Page 17 - stanochny park

P. 17

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

advantages

of

Integrated technology for the integrated EEA + MPM

The

the restoration of parts using technology are obvious:

metal-polymer materials ● surface continuity 100%;

● the roughness is much lower

than with EEA;

● hardness is much higher than

A new method for the restoration of that of MPM;

metal parts is proposed, including applying ● due to the possibility of applying

a combined coating to their worn surface by EEA coating using a wide

using electroerosive alloying and metal- range of materials (any

polymer material. conductive materials can be

used), it is possible to widely

vary the mechanical, thermal,

electrical and other properties

The restoration of parts and interfaces is the most important task of repair production. of the working surfaces of

The organization of parts restoration allows to save a significant amount of scarce materials, parts;

extend the life of parts by 2 ... 3 times, reduce the production of commercial spare parts at ● penetration of polymer

manufacturing plants and reduce the cost of repairing machinery and equipment. Efficiency and material into the depressions and

resource of restored parts make up on average 60 ... 80% of these indicators are relatively microroughness of the restored

new. However, currently there are technological methods with the help of which it is possible to part eliminates the likelihood of

completely restore the original resource of parts or even increase it. At the same time, there are corrosion in these dimples not filled

technologies having a number of advantages, but due to their shortcomings, their widespread with polymer material;

adoption in repair production is limited. Despite this, a combination of some methods of restoring ● the wear resistance, reliability and

parts allows to achieve the desired results. durability of the reconditioned parts

is higher than during restoration

using individual technologies.

Recently, in the repair industry, should be noted that repeated use of this method When using the

new technologies for repairing parts gradually reduces the dimensions of the part itself. integrated technology, various

and equipment using metal-polymer To compensate for this drawback, it is proposed to options for the formation of

materials (MPM), which have the the structure of the reduced

following properties, are increasingly use electroerosive alloying (EEA) before applying surface layer are possible

MPM.

used: When using EEA, the anode material (alloying (Figures 1a, 1b, 2).

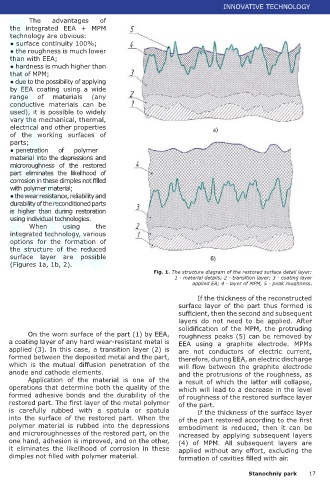

● good adhesion to metal; material) can form a coating layer extremely Fig. 1. The structure diagram of the restored surface detail layer:

● close to metal deformation characteristics; strongly adhered to the surface on the cathode 1 - material details; 2 - transition layer; 3 - coating layer

applied EA; 4 - layer of MPM, 5 - peak roughness.

● slight changes in properties with

temperature; surface (alloyed surface). In this case, there is no If the thickness of the reconstructed

interface between the deposited material and the

● minimal shrinkage during hardening; base metal, i.e. diffusion of anode elements into surface layer of the part thus formed is

● resistance to external factors; the cathode. sufficient, then the second and subsequent

● lack of external secretions affecting At the same time, the main disadvantage layers do not need to be applied. After

the metal; solidification of the MPM, the protruding

● minimal surface preparation; of EEA is an increase in the surface roughness of On the worn surface of the part (1) by EEA, roughness peaks (5) can be removed by

the products after processing, which in turn will

● hardening without pressure and without positively affect the adhesion quality of the MPM a coating layer of any hard wear-resistant metal is EEA using a graphite electrode. MPMs

elevated temperatures; layer with the workpiece. applied (3). In this case, a transition layer (2) is are not conductors of electric current,

● long life without changing the mechanical Considering the characteristic features of the formed between the deposited metal and the part, therefore, during EEA, an electric discharge

properties; which is the mutual diffusion penetration of the will flow between the graphite electrode

● environmental safety. EEA method described above, as well as the fact anode and cathode elements. and the protrusions of the roughness, as

that by varying the doping regimes, it is possible Application of the material is one of the

to widely vary the surface roughness (Rz) from 1 operations that determine both the quality of the a result of which the latter will collapse,

to 200 μm or more, an integrated technology is formed adhesive bonds and the durability of the which will lead to a decrease in the level

proposed for reconstructing parts, including the restored part. The first layer of the metal polymer of roughness of the restored surface layer

However, it should be noted that in electroerosion method doping followed by the is carefully rubbed with a spatula or spatula of the part.

If the thickness of the surface layer

order to achieve good adhesion of the plastic application of MPM. into the surface of the restored part. When the of the part restored according to the first

to the surface of the product being restored In this case, separately taken methods for polymer material is rubbed into the depressions embodiment is reduced, then it can be

on its surface, it is necessary to create the the restoration of parts (EEA and MPM application) and microroughnesses of the restored part, on the increased by applying subsequent layers

appropriate (required) roughness, which in no way reduce the strengths of each other, but one hand, adhesion is improved, and on the other, (4) of MPM. All subsequent layers are

is formed by special cleaning using an complement them and eliminate the disadvantages it eliminates the likelihood of corrosion in these applied without any effort, excluding the

abrasive wheel, grooving, milling, etc. It inherent in each individually. dimples not filled with polymer material. formation of cavities filled with air.

16 Stanochniy park Stanochniy park 17