Page 6 - October 2018

P. 6

Wing Structure:

By the end of May, the whole lower wing skin was

bonded in place. Then we temporarily placed the

four fuel tanks in their appropriate locations,

supported on a simple rope harness. The wing was

lifted high enough to allow parts of the wing jig

underneath it to be taken apart and disposed of.

Certain sections of the jigs were retained, and

wheels attached to the jigs for wing support during

additional work to be completed on the various

fittings later in the year.

We are still on target for the wings to be completed

to inspection level and re-attached to the fuselage by

the end of 2018, early 2019. The inspection will take Cutting the main undercarriage openings

place at a much later time after all the wing’s internal

fittings are in place. Only then will the upper wing

skins be bonded in place.

The wing was temporarily positioned back on the

fuselage for two reasons; so that the lower wing

skins could be trimmed to the required spacing from

the fuselage (the lower wing skin will have at

minimum a ¼” gap to the fuselage sides to allow for

flexing of the wing structure during turbulent flight

conditions), and secondly to verify the carbon fiber

engine mount anchor positions (these will be just

below the wing spar connections to the fuselage)

which will be extending forward from the engine

positions through two of the bulkheads in the

fuselage. The actual steel engine mounts will be

inserted and bolted in position at a later date.

The elevon (combination elevator and aileron)

positions were cut out at the rear of the wing and the

edges fibre-glassed for strength. Final trimming will

take place during the elevon fitting most likely in late

2019.

The wing was positioned in its ground attitude and

water was poured into the various sections of the Drilling the drain holes in the wing ribs

wing structure to determine the optimum position for Fuselage:

water drainage holes to be drilled to accommodate The fuselage underside will be receiving the

the condensation drainage requirements within the finishing surface application of epoxy

wing.

compounds during this coming quarter before

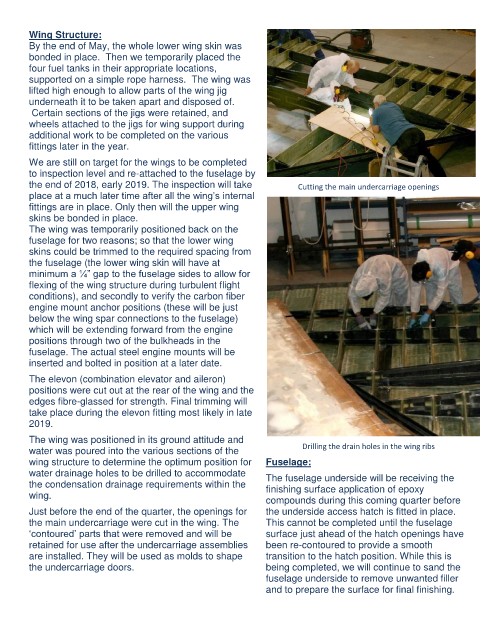

Just before the end of the quarter, the openings for the underside access hatch is fitted in place.

the main undercarriage were cut in the wing. The This cannot be completed until the fuselage

‘contoured’ parts that were removed and will be surface just ahead of the hatch openings have

retained for use after the undercarriage assemblies been re-contoured to provide a smooth

are installed. They will be used as molds to shape transition to the hatch position. While this is

the undercarriage doors. being completed, we will continue to sand the

fuselage underside to remove unwanted filler

and to prepare the surface for final finishing.