Page 345 - Six Sigma Advanced Tools for Black Belts and Master Black Belts

P. 345

OTE/SPH

OTE/SPH

3:7

August 31, 2006

Char Count= 0

JWBK119-21

330 Establishing Cumulative Conformance Count Charts

400.0

350.0

300.0

250.0

ARL 200.0

150.0

100.0 n = 10000 n = 20000

n = 50000 n = 100000

50.0

Known p

00

0.000 0.500 1.000 1.500 2.000 2.500

p = p/p 0

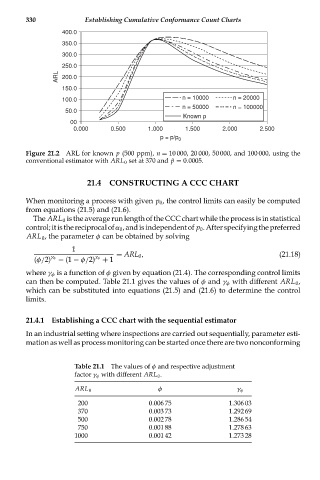

Figure 21.2 ARL for known p (500 ppm), n = 10 000, 20 000, 50 000, and 100 000, using the

conventional estimator with ARL 0 set at 370 and ˆp = 0.0005.

21.4 CONSTRUCTING A CCC CHART

When monitoring a process with given p 0 , the control limits can easily be computed

from equations (21.5) and (21.6).

The ARL 0 is the average run length of the CCC chart while the process is in statistical

control;itisthereciprocalofα 0 ,andisindependentof p 0 .Afterspecifyingthepreferred

ARL 0 , the parameter φ can be obtained by solving

1

= ARL 0 , (21.18)

γ φ

γ φ

(φ/2) − (1 − φ/2) + 1

where γ φ is a function of φ given by equation (21.4). The corresponding control limits

can then be computed. Table 21.1 gives the values of φ and γ φ with different ARL 0 ,

which can be substituted into equations (21.5) and (21.6) to determine the control

limits.

21.4.1 Establishing a CCC chart with the sequential estimator

In an industrial setting where inspections are carried out sequentially, parameter esti-

mation as well as process monitoring can be started once there are two nonconforming

Table 21.1 The values of φ and respective adjustment

factor γ φ with different ARL 0 .

ARL 0 φ γ φ

200 0.006 75 1.306 03

370 0.003 73 1.292 69

500 0.002 78 1.286 54

750 0.001 88 1.278 63

1000 0.001 42 1.273 28