Page 1888 - Flipbook_SolidDesignSoutheast2020

P. 1888

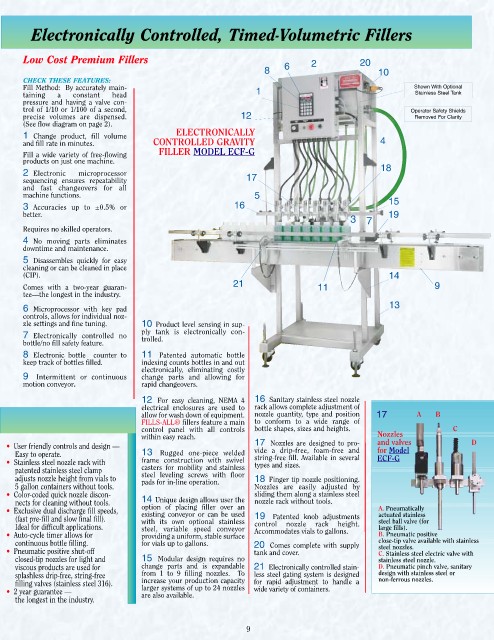

Electronically Controlled, Timed-Volumetric Fillers

Low Cost Premium Fillers 2 20

8 6 10

CHECK THESE FEATURES:

Fill Method: By accurately main- 1 Shown With Optional

taining a constant head Stainless Steel Tank

pressure and having a valve con-

trol of 1/10 or 1/100 of a second, Operator Safety Shields

precise volumes are dispensed. 12 Removed For Clarity

(See flow diagram on page 2).

ELECTRONICALLY

1 Change product, fill volume

and fill rate in minutes. CONTROLLED GRAVITY 4

FILLER MODEL ECF-G

Fill a wide variety of free-flowing

products on just one machine.

18

2 Electronic microprocessor

sequencing ensures repeatability 17

and fast changeovers for all

machine functions. 5 15

3 Accuracies up to ±0.5% or 16

better. 19

3 7

Requires no skilled operators.

4 No moving parts eliminates

downtime and maintenance.

5 Disassembles quickly for easy

cleaning or can be cleaned in place

(CIP). 14

21

Comes with a two-year guaran- 11 9

tee—the longest in the industry.

13

6 Microprocessor with key pad

controls, allows for individual noz-

zle settings and fine tuning. 10 Product level sensing in sup-

ply tank is electronically con-

7 Electronically controlled no

bottle/no fill safety feature. trolled.

8 Electronic bottle counter to 11 Patented automatic bottle

keep track of bottles filled. indexing counts bottles in and out

electronically, eliminating costly

9 Intermittent or continuous change parts and allowing for

motion conveyor. rapid changeovers.

12 For easy cleaning, NEMA 4 16 Sanitary stainless steel nozzle

electrical enclosures are used to rack allows complete adjustment of

allow for wash down of equipment. nozzle quantity, type and position 17 A B

FILLS-ALL® fillers feature a main to conform to a wide range of

control panel with all controls bottle shapes, sizes and heights. C

within easy reach. Nozzles

• User friendly controls and design — 17 Nozzles are designed to pro- and valves D

for Model

vide a drip-free, foam-free and

Easy to operate. 13 Rugged one-piece welded string-free fill. Available in several

• Stainless steel nozzle rack with frame construction with swivel types and sizes. ECF-G

patented stainless steel clamp casters for mobility and stainless

adjusts nozzle height from vials to steel leveling screws with floor 18 Finger tip nozzle positioning.

pads for in-line operation.

5 gallon containers without tools. Nozzles are easily adjusted by

• Color-coded quick nozzle discon- sliding them along a stainless steel

nects for cleaning without tools. 14 Unique design allows user the nozzle rack without tools.

• Exclusive dual discharge fill speeds, option of placing filler over an A. Pneumatically

existing conveyor or can be used

actuated stainless

(fast pre-fill and slow final fill). with its own optional stainless 19 Patented knob adjustments steel ball valve (for

Ideal for difficult applications. steel, variable speed conveyor control nozzle rack height. large fills).

• Auto-cycle timer allows for providing a uniform, stable surface Accommodates vials to gallons. B. Pneumatic positive

continuous bottle filling. for vials up to gallons. 20 Comes complete with supply close-tip valve available with stainless

• Pneumatic positive shut-off tank and cover. steel nozzles.

C. Stainless steel electric valve with

closed-tip nozzles for light and 15 Modular design requires no stainless steel nozzle.

viscous products are used for change parts and is expandable 21 Electronically controlled stain- D. Pneumatic pinch valve, sanitary

splashless drip-free, string-free from 1 to 9 filling nozzles. To less steel gating system is designed design with stainless steel or

non-ferrous nozzles.

filling valves (stainless steel 316). increase your production capacity for rapid adjustment to handle a

• 2 year guarantee — larger systems of up to 24 nozzles wide variety of containers.

are also available.

the longest in the industry.

9