Page 1884 - Flipbook_SolidDesignSoutheast2020

P. 1884

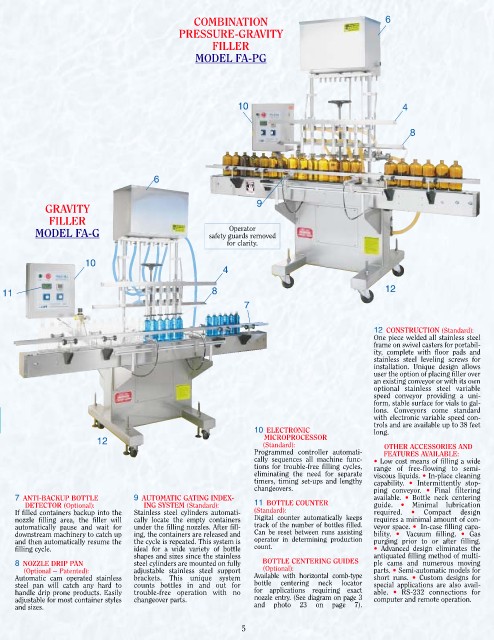

COMBINATION 6

PRESSURE-GRAVITY

FILLER

MODEL FA-PG

10 4

8

6

9

GRAVITY

FILLER

Operator

MODEL FA-G safety guards removed

for clarity.

10

4

11 8 12

7

12 CONSTRUCTION (Standard):

One piece welded all stainless steel

frame on swivel casters for portabil-

ity, complete with floor pads and

stainless steel leveling screws for

installation. Unique design allows

user the option of placing filler over

an existing conveyor or with its own

optional stainless steel variable

speed conveyor providing a uni-

form, stable surface for vials to gal-

lons. Conveyors come standard

with electronic variable speed con-

trols and are available up to 38 feet

10 ELECTRONIC long.

MICROPROCESSOR

12 (Standard):

Programmed controller automati- OTHER ACCESSORIES AND

FEATURES AVAILABLE:

cally sequences all machine func- • Low cost means of filling a wide

tions for trouble-free filling cycles, range of free-flowing to semi-

eliminating the need for separate viscous liquids. • In-place cleaning

timers, timing set-ups and lengthy capability. • Intermittently stop-

changeovers. ping conveyor. • Final filtering

7 ANTI-BACKUP BOTTLE 9 AUTOMATIC GATING INDEX- available. • Bottle neck centering

DETECTOR (Optional): ING SYSTEM (Standard): 11 BOTTLE COUNTER guide. • Minimal lubrication

If filled containers backup into the Stainless steel cylinders automati- (Standard): required. • Compact design

nozzle filling area, the filler will cally locate the empty containers Digital counter automatically keeps requires a minimal amount of con-

automatically pause and wait for under the filling nozzles. After fill- track of the number of bottles filled. veyor space. • In-case filling capa-

downstream machinery to catch up ing, the containers are released and Can be reset between runs assisting bility. • Vacuum filling. • Gas

and then automatically resume the the cycle is repeated. This system is operator in determining production purging prior to or after filling.

filling cycle. ideal for a wide variety of bottle count. • Advanced design eliminates the

shapes and sizes since the stainless antiquated filling method of multi-

8 NOZZLE DRIP PAN steel cylinders are mounted on fully BOTTLE CENTERING GUIDES ple cams and numerous moving

(Optional — Patented): adjustable stainless steel support (Optional): parts. • Semi-automatic models for

Automatic cam operated stainless brackets. This unique system Available with horizontal comb-type short runs. • Custom designs for

steel pan will catch any hard to counts bottles in and out for bottle centering neck locator special applications are also avail-

handle drip prone products. Easily trouble-free operation with no for applications requiring exact able. • RS-232 connections for

adjustable for most container styles changeover parts. nozzle entry. (See diagram on page 3 computer and remote operation.

and sizes. and photo 23 on page 7).

5