Page 1885 - Flipbook_SolidDesignSoutheast2020

P. 1885

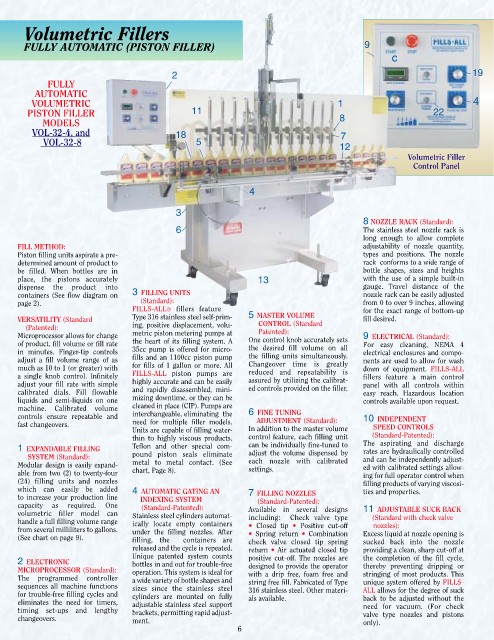

Volumetric Fillers

FULLY AUTOMATIC (PISTON FILLER) 9

c

2 19

FULLY

AUTOMATIC

VOLUMETRIC 1 4

PISTON FILLER 11 22

MODELS 8

VOL-32-4, and 18 7

VOL-32-8 5

12

Volumetric Filler

Control Panel

4

3

8 NOZZLE RACK (Standard):

6 The stainless steel nozzle rack is

long enough to allow complete

FILL METHOD: adjustability of nozzle quantity,

Piston filling units aspirate a pre- types and positions. The nozzle

determined amount of product to rack conforms to a wide range of

be filled. When bottles are in bottle shapes, sizes and heights

place, the pistons accurately 13 with the use of a simple built-in

dispense the product into gauge. Travel distance of the

containers (See flow diagram on 3 FILLING UNITS nozzle rack can be easily adjusted

page 2). (Standard): from 0 to over 9 inches, allowing

FILLS-ALL® fillers feature for the exact range of bottom-up

Type 316 stainless steel self-prim- 5 MASTER VOLUME

VERSATILITY (Standard CONTROL (Standard fill desired.

(Patented): ing, positive displacement, volu-

Patented):

Microprocessor allows for change metric piston metering pumps at One control knob accurately sets 9 ELECTRICAL (Standard):

of product, fill volume or fill rate the heart of its filling system. A the desired fill volume on all For easy cleaning, NEMA 4

in minutes. Finger-tip controls 35cc pump is offered for micro- the filling units simultaneously. electrical enclosures and compo-

adjust a fill volume range of as fills and an 1100cc piston pump Changeover time is greatly nents are used to allow for wash

much as 10 to 1 (or greater) with for fills of 1 gallon or more. All reduced and repeatability is down of equipment. FILLS-ALL

a single knob control. Infinitely FILLS-ALL piston pumps are assured by utilizing the calibrat- fillers feature a main control

adjust your fill rate with simple highly accurate and can be easily ed controls provided on the filler. panel with all controls within

calibrated dials. Fill flowable and rapidly disassembled, mini- easy reach. Hazardous location

liquids and semi-liquids on one mizing downtime, or they can be controls available upon request.

machine. Calibrated volume cleaned in place (CIP). Pumps are 6 FINE TUNING

controls ensure repeatable and interchangeable, eliminating the ADJUSTMENT (Standard): 10 INDEPENDENT

fast changeovers. need for multiple filler models. SPEED CONTROLS

Units are capable of filling water- In addition to the master volume

(Standard-Patented):

thin to highly viscous products. control feature, each filling unit The aspirating and discharge

1 EXPANDABLE FILLING Teflon and other special com- can be individually fine-tuned to rates are hydraulically controlled

adjust the volume dispensed by

SYSTEM (Standard): pound piston seals eliminate and can be independently adjust-

Modular design is easily expand- metal to metal contact. (See each nozzle with calibrated ed with calibrated settings allow-

settings.

able from two (2) to twenty-four chart, Page 8). ing for full operator control when

(24) filling units and nozzles filling products of varying viscosi-

which can easily be added 4 AUTOMATIC GATING AN 7 FILLING NOZZLES ties and properties.

to increase your production line INDEXING SYSTEM (Standard-Patented):

capacity as required. One (Standard-Patented): Available in several designs 11 ADJUSTABLE SUCK BACK

volumetric filler model can Stainless steel cylinders automat- including: Check valve type (Standard with check valve

handle a full filling volume range ically locate empty containers • Closed tip • Positive cut-off nozzles):

from several milliliters to gallons. under the filling nozzles. After • Spring return • Combination Excess liquid at nozzle opening is

(See chart on page 9). filling, the containers are check valve closed tip spring sucked back into the nozzle

released and the cycle is repeated. return • Air actuated closed tip providing a clean, sharp cut-off at

Unique patented system counts positive cut-off. The nozzles are the completion of the fill cycle,

2 ELECTRONIC bottles in and out for trouble-free designed to provide the operator thereby preventing dripping or

MICROPROCESSOR (Standard): operation. This system is ideal for with a drip free, foam free and stringing of most products. This

The programmed controller a wide variety of bottle shapes and string free fill. Fabricated of Type unique system offered by FILLS-

sequences all machine functions sizes since the stainless steel 316 stainless steel. Other materi- ALL allows for the degree of suck

for trouble-free filling cycles and cylinders are mounted on fully als available. back to be adjusted without the

eliminates the need for timers, adjustable stainless steel support need for vacuum. (For check

timing set-ups and lengthy brackets, permitting rapid adjust- valve type nozzles and pistons

changeovers. ment. only).

6