Page 2805 - Flipbook_SolidDesignSoutheast2020

P. 2805

TITAN SHREDDERS

Reduce size and volume of bulk waste, scrap and out-of-spec materials

Munson’s Titan Shredder Tight tolerances between the It is constructed of carbon steel

reduces the volume of industrial, cutting surfaces of the rotors and as standard, and available in

medical and consumer waste side-mounted combs eliminate stainless steel with optional

including scrap plastics, fibrous or minimize binding or plugging, smart-auto-reversing controls,

products, fiberglass, wood while imparting little or no heat ram feeders, extended support

products, paper/cardboard, to the material, depending on legs, specialized hoppers, and

application. standard gravity-discharge

outlets or transitions for

The cutter heads are mounted pneumatic collection.

along two parallel shafts that

are hexagonal in cross section, Munson also offers Maxum

yielding greater strength, higher Crushers with conical, solid

fatigue resistance and less carbide tips able to crush

deflection than traditional materials that are too hard,

keyed bar shafts. The heads dense, cohesive or abrasive

are constructed of proprietary to shred.

steel that is heat-treated and

through-hardened, yet allows When primary shredding must

re-sharpening of the cutter tips. be followed by secondary size

reduction, Titan Shredders

The shredder is offered in three are often paired with Screen

widths: 28 in. (711 mm) with Classifying Cutters, Hammer

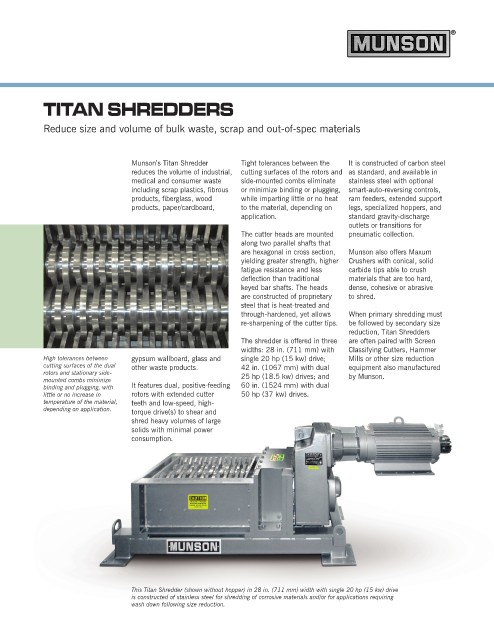

High tolerances between gypsum wallboard, glass and single 20 hp (15 kw) drive; Mills or other size reduction

cutting surfaces of the dual other waste products. 42 in. (1067 mm) with dual equipment also manufactured

rotors and stationary side- 25 hp (18.5 kw) drives; and by Munson.

mounted combs minimize

binding and plugging, with It features dual, positive-feeding 60 in. (1524 mm) with dual

little or no increase in rotors with extended cutter 50 hp (37 kw) drives.

temperature of the material, teeth and low-speed, high-

depending on application. torque drive(s) to shear and

shred heavy volumes of large

solids with minimal power

consumption.

This Titan Shredder (shown without hopper) in 28 in. (711 mm) width with single 20 hp (15 kw) drive

is constructed of stainless steel for shredding of corrosive materials and/or for applications requiring

wash down following size reduction.