Page 2810 - Flipbook_SolidDesignSoutheast2020

P. 2810

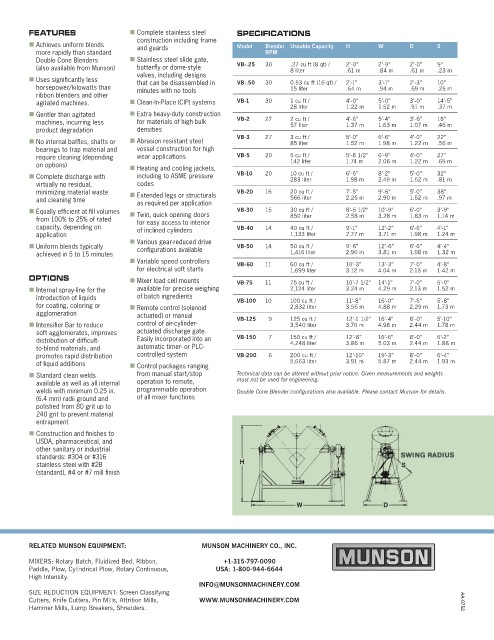

FEATURES n Complete stainless steel SPECIFICATIONS

construction including frame

n Achieves uniform blends and guards Model Blender Useable Capacity H W D S

more rapidly than standard RPM

Double Cone Blenders n Stainless steel slide gate,

(also available from Munson) butterfly or dome-style VB-.25 30 .27 cu ft (8 qt) / 2’-0” 2’-9” 2’-0” 9”

.61 m

8 liter

.23 m

.84 m

.61 m

valves, including designs

n Uses significantly less that can be disassembled in VB-.50 30 0.53 cu ft (16 qt) / 2’-1” 3’-1” 2’-3” 10”

horsepower/kilowatts than minutes with no tools 15 liter .64 m .94 m .69 m .25 m

ribbon blenders and other

agitated machines. n Clean-In-Place (CIP) systems VB-1 30 1 cu ft / 4’-0” 5’-0” 3’-0” 14’-5”

28 liter 1.22 m 1.52 m .91 m .37 m

n Gentler than agitated n Extra heavy-duty construction

machines, incurring less for materials of high bulk VB-2 27 2 cu ft / 4’-6” 5’-4” 3’-6” 18”

1.07 m

1.37 m

1.63 m

.46 m

57 liter

product degradation densities

VB-3 27 3 cu ft / 5’-0” 6’-6” 4’-0” 22”

n No internal baffles, shafts or n Abrasion resistant steel 85 liter 1.52 m 1.98 m 1.22 m .56 m

bearings to trap material and vessel construction for high

require cleaning (depending wear applications VB-5 20 5 cu ft / 5’-8 1/2” 6’-9” 4’-0” 27”

on options) n Heating and cooling jackets, 142 liter 1.74 m 2.06 m 1.22 m .69 m

n Complete discharge with including to ASME pressure VB-10 20 10 cu ft / 6’-6” 8’-2” 5’-0” 32”

1.52 m

283 liter

2.49 m

.81 m

1.98 m

virtually no residual, codes

minimizing material waste n Extended legs or structurals VB-20 16 20 cu ft / 7’-5” 9’-6” 5’-0” 38”

and cleaning time as required per application 566 liter 2.26 m 2.90 m 1.52 m .97 m

n Equally efficient at fill volumes n Twin, quick opening doors VB-30 15 30 cu ft / 8’-5 1/2” 10’-9” 6’-0” 3’-9”

from 100% to 25% of rated for easy access to interior 850 liter 2.58 m 3.28 m 1.83 m 1.14 m

capacity, depending on of inclined cylinders VB-40 14 40 cu ft / 9’-1” 12’-2” 6’-6” 4’-1”

application 1,133 liter 2.77 m 3.71 m 1.98 m 1.24 m

n Various gear-reduced drive

n Uniform blends typically configurations available VB-50 14 50 cu ft / 9’-6” 12’-6” 6’-6” 4’-4”

achieved in 5 to 15 minutes 1,416 liter 2.90 m 3.81 m 1.98 m 1.32 m

n Variable speed controllers VB-60 11 60 cu ft / 10’-3” 13’-3” 7’-0” 4’-8”

for electrical soft starts 1,699 liter 3.12 m 4.04 m 2.13 m 1.42 m

OPTIONS n Mixer load cell mounts VB-75 11 75 cu ft / 10’-7 1/2” 14’-1” 7’-0” 5’-0”

n nternal spray-line for the available for precise weighing 2,124 liter 3.24 m 4.29 m 2.13 m 1.52 m

I

introduction of liquids of batch ingredients VB-100 10 100 cu ft / 11’-8” 16’-0” 7’-6” 5’-8”

for coating, coloring or n Remote control (solenoid 2,832 liter 3.56 m 4.88 m 2.29 m 1.73 m

agglomeration actuated) or manual

I

n ntensifier Bar to reduce control of air-cylinder- VB-125 9 125 cu ft / 12’-1 1/2” 16’-4” 8’-0” 5’-10”

1.78 m

2.44 m

4.98 m

3.70 m

3,540 liter

soft agglomerates, improves actuated discharge gate.

distribution of difficult- Easily incorporated into an VB-150 7 150 cu ft / 12’-8” 16’-6” 8’-0” 6’-2”

1.88 m

4,248 liter

2.44 m

3.86 m

5.03 m

to-blend materials, and automatic timer- or PLC-

promotes rapid distribution controlled system VB-200 6 200 cu ft / 12’-10” 19’-3” 8’-0” 6’-4”

of liquid additions n Control packages ranging 5,663 liter 3.91 m 5.87 m 2.44 m 1.93 m

n Standard clean welds from manual start/stop Technical data can be altered without prior notice. Given measurements and weights

available as well as all internal operation to remote, must not be used for engineering.

welds with minimum 0.25 in. programmable operation Double Cone Blender configurations also available. Please contact Munson for details.

(6.4 mm) radii ground and of all mixer functions

polished from 80 grit up to

240 grit to prevent material

entrapment

n Construction and finishes to

USDA, pharmaceutical, and

other sanitary or industrial

standards: #304 or #316

stainless steel with #2B

(standard), #4 or #7 mill finish

ReLaTeD MUnSon eQUiPMenT: MUnSon MaCHineRy Co., inC.

MIXERS: Rotary Batch, Fluidized Bed, Ribbon, +1-315-797-0090

Paddle, Plow, Cylindrical Plow, Rotary Continuous, USa: 1-800-944-6644

High Intensity.

info@MUnSonMaCHineRy.CoM

SIZE REDUCTION EQUIPMENT: Screen Classifying

Cutters, Knife Cutters, Pin Mills, Attrition Mills, WWW.MUnSonMaCHineRy.CoM AA-0752

Hammer Mills, Lump Breakers, Shredders.