Page 2904 - Flipbook_SolidDesignSoutheast2020

P. 2904

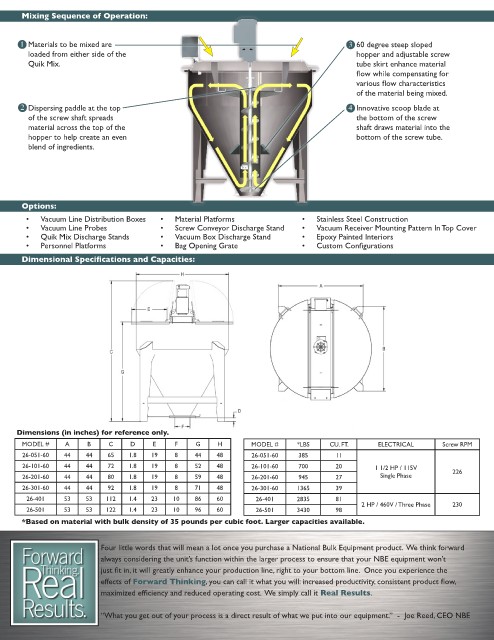

Mixing Sequence of Operation:

1 Materials to be mixed are 3 60 degree steep sloped

loaded from either side of the hopper and adjustable screw

Quik Mix. tube skirt enhance material

flow while compensating for

various flow characteristics

of the material being mixed.

2 Dispersing paddle at the top 4 Innovative scoop blade at

of the screw shaft spreads the bottom of the screw

material across the top of the shaft draws material into the

hopper to help create an even bottom of the screw tube.

blend of ingredients.

Options:

• Vacuum Line Distribution Boxes • Material Platforms • Stainless Steel Construction

• Vacuum Line Probes • Screw Conveyor Discharge Stand • Vacuum Receiver Mounting Pattern In Top Cover

• Quik Mix Discharge Stands • Vacuum Box Discharge Stand • Epoxy Painted Interiors

• Personnel Platforms • Bag Opening Grate • Custom Configurations

Dimensional Specifications and Capacities:

Dimensions (in inches) for reference only.

MODEL # A B C D E F G H MODEL # *LBS CU. FT. ELECTRICAL Screw RPM

26-051-60 44 44 65 1.8 19 8 44 48 26-051-60 385 11

26-101-60 44 44 72 1.8 19 8 52 48 26-101-60 700 20 1 1/2 HP / 115V

26-201-60 44 44 80 1.8 19 8 59 48 26-201-60 945 27 Single Phase 226

26-301-60 44 44 92 1.8 19 8 71 48 26-301-60 1365 39

26-401 53 53 112 1.4 23 10 86 60 26-401 2835 81

2 HP / 460V / Three Phase 230

26-501 53 53 122 1.4 23 10 96 60 26-501 3430 98

*Based on material with bulk density of 35 pounds per cubic foot. Larger capacities available.

Four little words that will mean a lot once you purchase a National Bulk Equipment product. We think forward

always considering the unit’s function within the larger process to ensure that your NBE equipment won’t

just fit in, it will greatly enhance your production line, right to your bottom line. Once you experience the

effects of Forward Thinking, you can call it what you will: increased productivity, consistent product flow,

maximized efficiency and reduced operating cost. We simply call it Real Results.

“What you get out of your process is a direct result of what we put into our equipment.” - Joe Reed, CEO NBE