Page 2908 - Flipbook_SolidDesignSoutheast2020

P. 2908

Conveying & Process Interface

A wide variety of options are available to

integrate the bulk bag discharger with material

conveying systems and downstream process

equipment. The material characteristics and

the specifics of the customer’s application

dictate the type of interface utilized.

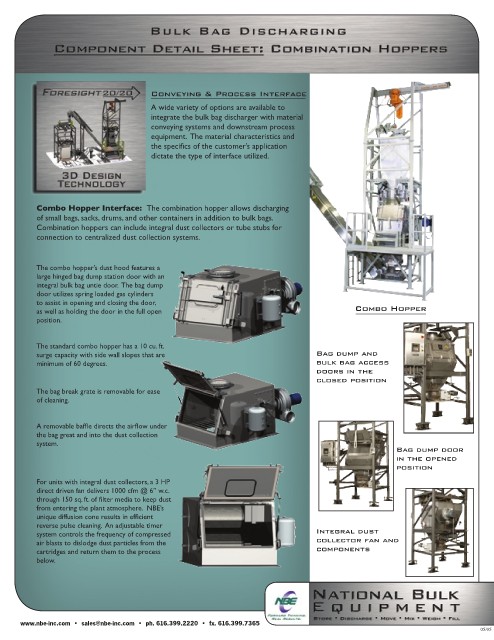

Combo Hopper Interface: The combination hopper allows discharging

of small bags, sacks, drums, and other containers in addition to bulk bags.

Combination hoppers can include integral dust collectors or tube stubs for

connection to centralized dust collection systems.

The combo hopper’s dust hood features a

large hinged bag dump station door with an

integral bulk bag untie door. The bag dump

door utilizes spring loaded gas cylinders

to assist in opening and closing the door,

as well as holding the door in the full open Combo Hopper

position.

The standard combo hopper has a 10 cu. ft.

surge capacity with side wall slopes that are Bag dump and

minimum of 60 degrees. bulk bag access

doors in the

closed position

The bag break grate is removable for ease

of cleaning.

A removable baffle directs the airflow under

the bag great and into the dust collection

system.

Bag dump door

in the opened

position

For units with integral dust collectors, a 3 HP

direct driven fan delivers 1000 cfm @ 6” w.c.

through 150 sq. ft. of filter media to keep dust

from entering the plant atmosphere. NBE’s

unique diffusion cone results in efficient

reverse pulse cleaning. An adjustable timer

system controls the frequency of compressed Integral dust

air blasts to dislodge dust particles from the collector fan and

cartridges and return them to the process components

below.

www.nbe-inc.com • sales@nbe-inc.com • ph. 616.399.2220 • fx. 616.399.7365

05/05