Page 2912 - Flipbook_SolidDesignSoutheast2020

P. 2912

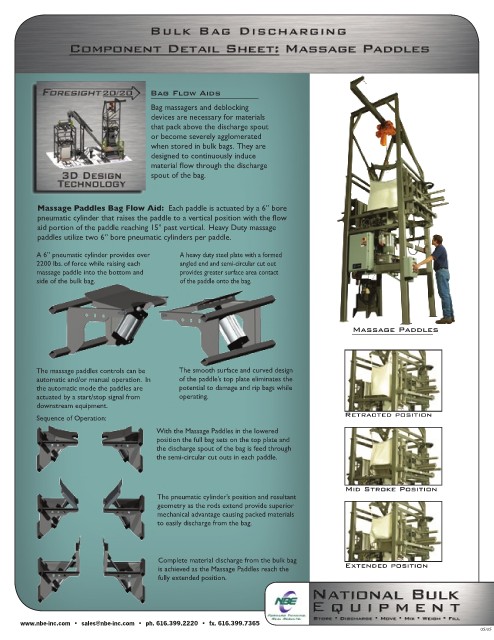

Bag Flow Aids

Bag massagers and deblocking

devices are necessary for materials

that pack above the discharge spout

or become severely agglomerated

when stored in bulk bags. They are

designed to continuously induce

material flow through the discharge

spout of the bag.

Massage Paddles Bag Flow Aid: Each paddle is actuated by a 6” bore

pneumatic cylinder that raises the paddle to a vertical position with the flow

aid portion of the paddle reaching 15° past vertical. Heavy Duty massage

paddles utilize two 6” bore pneumatic cylinders per paddle.

A 6” pneumatic cylinder provides over A heavy duty steel plate with a formed

2200 lbs. of force while raising each angled end and semi-circular cut out

massage paddle into the bottom and provides greater surface area contact

side of the bulk bag. of the paddle onto the bag.

Massage Paddles

The massage paddles controls can be The smooth surface and curved design

automatic and/or manual operation. In of the paddle’s top plate eliminates the

the automatic mode the paddles are potential to damage and rip bags while

actuated by a start/stop signal from operating.

downstream equipment.

Sequence of Operation: Retracted position

With the Massage Paddles in the lowered

position the full bag sets on the top plate and

the discharge spout of the bag is feed through

the semi-circular cut outs in each paddle.

Mid Stroke Position

The pneumatic cylinder’s position and resultant

geometry as the rods extend provide superior

mechanical advantage causing packed materials

to easily discharge from the bag.

Complete material discharge from the bulk bag

is achieved as the Massage Paddles reach the Extended position

fully extended position.

www.nbe-inc.com • sales@nbe-inc.com • ph. 616.399.2220 • fx. 616.399.7365

05/05