Page 2917 - Flipbook_SolidDesignSoutheast2020

P. 2917

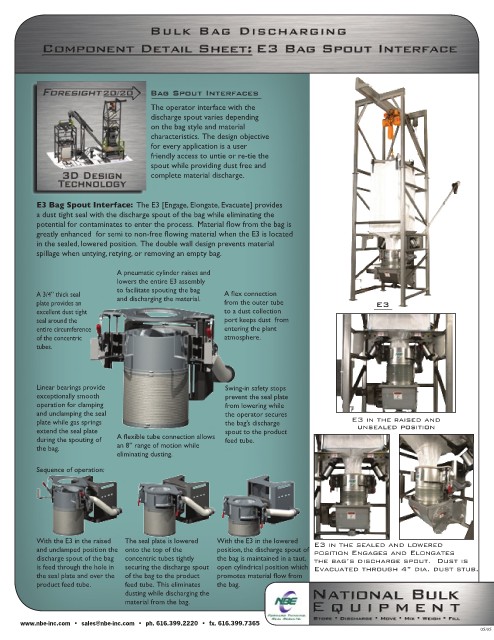

Bag Spout Interfaces

The operator interface with the

discharge spout varies depending

on the bag style and material

characteristics. The design objective

for every application is a user

friendly access to untie or re-tie the

spout while providing dust free and

complete material discharge.

E3 Bag Spout Interface: The E3 [Engage, Elongate, Evacuate] provides

a dust tight seal with the discharge spout of the bag while eliminating the

potential for contaminates to enter the process. Material flow from the bag is

greatly enhanced for semi to non-free flowing material when the E3 is located

in the sealed, lowered position. The double wall design prevents material

spillage when untying, retying, or removing an empty bag.

A pneumatic cylinder raises and

lowers the entire E3 assembly

to facilitate spouting the bag

A 3/4” thick seal and discharging the material. A flex connection

plate provides an from the outer tube E3

excellent dust tight to a dust collection

seal around the port keeps dust from

entire circumference entering the plant

of the concentric atmosphere.

tubes.

Linear bearings provide Swing-in safety stops

exceptionally smooth prevent the seal plate

operation for clamping from lowering while

and unclamping the seal the operator secures

plate while gas springs the bag’s discharge E3 in the raised and

extend the seal plate spout to the product unsealed position

during the spouting of A flexible tube connection allows feed tube.

the bag. an 8” range of motion while

eliminating dusting.

Sequence of operation:

With the E3 in the raised The seal plate is lowered With the E3 in the lowered E3 in the sealed and lowered

and unclamped position the onto the top of the position, the discharge spout of position Engages and Elongates

discharge spout of the bag concentric tubes tightly the bag is maintained in a taut, the bag’s discharge spout. Dust is

is feed through the hole in securing the discharge spout open cylindrical position which Evacuated through 4” dia. dust stub.

the seal plate and over the of the bag to the product promotes material flow from

product feed tube. feed tube. This eliminates the bag.

dusting while discharging the

material from the bag.

www.nbe-inc.com • sales@nbe-inc.com • ph. 616.399.2220 • fx. 616.399.7365

05/05