Page 2915 - Flipbook_SolidDesignSoutheast2020

P. 2915

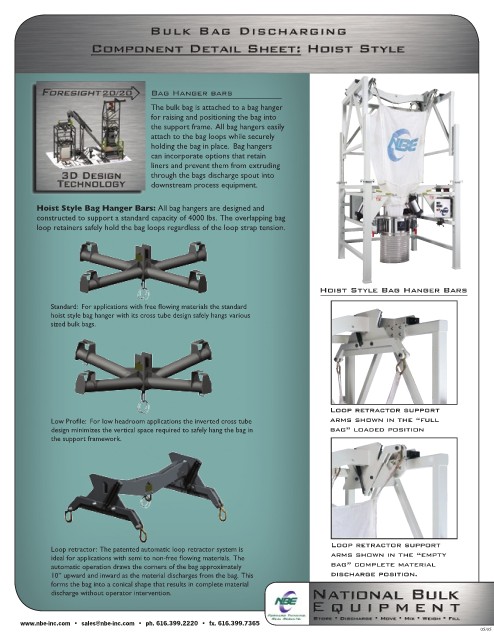

Bag Hanger bars

The bulk bag is attached to a bag hanger

for raising and positioning the bag into

the support frame. All bag hangers easily

attach to the bag loops while securely

holding the bag in place. Bag hangers

can incorporate options that retain

liners and prevent them from extruding

through the bags discharge spout into

downstream process equipment.

Hoist Style Bag Hanger Bars: All bag hangers are designed and

constructed to support a standard capacity of 4000 lbs. The overlapping bag

loop retainers safely hold the bag loops regardless of the loop strap tension.

Hoist Style Bag Hanger Bars

Standard: For applications with free flowing materials the standard

hoist style bag hanger with its cross tube design safely hangs various

sized bulk bags.

Loop retractor support

Low Profile: For low headroom applications the inverted cross tube arms shown in the “full

design minimizes the vertical space required to safely hang the bag in bag” loaded position

the support framework.

Loop retractor support

Loop retractor: The patented automatic loop retractor system is

ideal for applications with semi to non-free flowing materials. The arms shown in the “empty

automatic operation draws the corners of the bag approximately bag” complete material

10” upward and inward as the material discharges from the bag. This discharge position.

forms the bag into a conical shape that results in complete material

discharge without operator intervention.

www.nbe-inc.com • sales@nbe-inc.com • ph. 616.399.2220 • fx. 616.399.7365

05/05