Page 2910 - Flipbook_SolidDesignSoutheast2020

P. 2910

Conveying & Process Interface

A wide variety of options are available to

integrate the bulk bag discharger with material

conveying systems and downstream process

equipment. The material characteristics and

the specifics of the customer’s application

dictate the type of interface utilized.

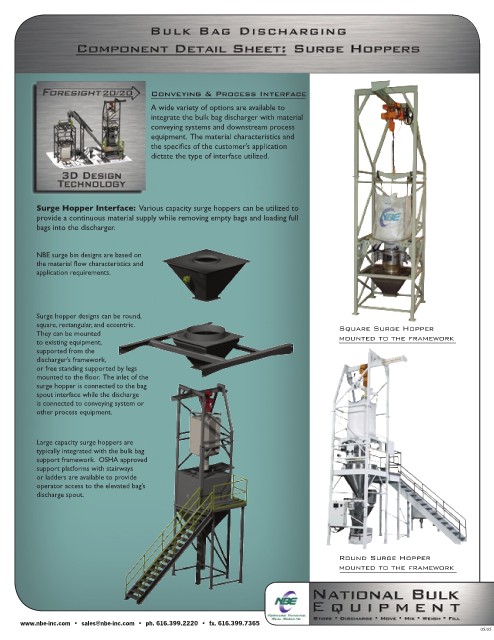

Surge Hopper Interface: Various capacity surge hoppers can be utilized to

provide a continuous material supply while removing empty bags and loading full

bags into the discharger.

NBE surge bin designs are based on

the material flow characteristics and

application requirements.

Surge hopper designs can be round,

square, rectangular, and eccentric. Square Surge Hopper

They can be mounted

to existing equipment, mounted to the framework

supported from the

discharger’s framework,

or free standing supported by legs

mounted to the floor. The inlet of the

surge hopper is connected to the bag

spout interface while the discharge

is connected to conveying system or

other process equipment.

Large capacity surge hoppers are

typically integrated with the bulk bag

support framework. OSHA approved

support platforms with stairways

or ladders are available to provide

operator access to the elevated bag’s

discharge spout.

Round Surge Hopper

mounted to the framework

www.nbe-inc.com • sales@nbe-inc.com • ph. 616.399.2220 • fx. 616.399.7365

05/05