Page 2909 - Flipbook_SolidDesignSoutheast2020

P. 2909

Conveying & Process Interface

A wide variety of options are available to

integrate the bulk bag discharger with material

conveying systems and downstream process

equipment. The material characteristics and

the specifics of the customer’s application

dictate the type of interface utilized.

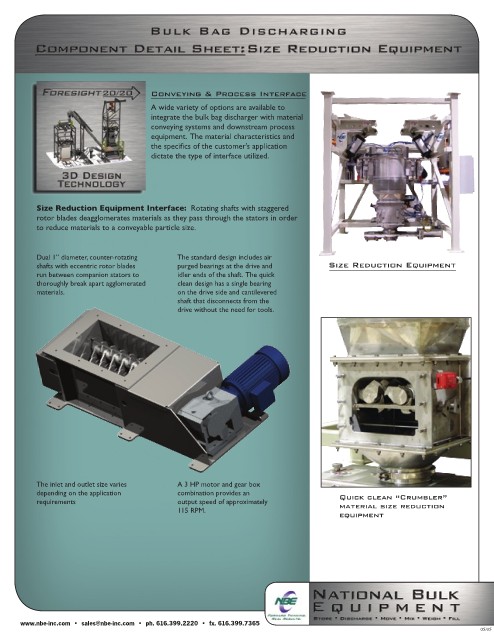

Size Reduction Equipment Interface: Rotating shafts with staggered

rotor blades deagglomerates materials as they pass through the stators in order

to reduce materials to a conveyable particle size.

Dual 1” diameter, counter-rotating The standard design includes air

shafts with eccentric rotor blades purged bearings at the drive and Size Reduction Equipment

run between companion stators to idler ends of the shaft. The quick

thoroughly break apart agglomerated clean design has a single bearing

materials. on the drive side and cantilevered

shaft that disconnects from the

drive without the need for tools.

The inlet and outlet size varies A 3 HP motor and gear box

depending on the application combination provides an Quick clean “Crumbler”

requirements output speed of approximately material size reduction

115 RPM.

equipment

www.nbe-inc.com • sales@nbe-inc.com • ph. 616.399.2220 • fx. 616.399.7365

05/05