Page 3049 - Flipbook_SolidDesignSoutheast2020

P. 3049

DESIGN FACTORS

Sale Technical Sheet

69 William Street, Belleville, NJ 07109 STS Number ________

PH: 973-759-4600 * Fax: 973-759-6449 Effective Date _______

EMAIL: info@vac-u-max.com Supersedes _________

WEB SITE: www.vac-u-max.com

Review routing

Review the pipeline routing and see if the number of bends might be reduced. Blind tees or sharp elbows

should be exchanged for short-radius bends. For high-pressure systems with a single-bore pipeline,

stepping the pipeline to a larger bore part way along, could also increase throughput.

Remember the potential role that equipment wear can play on system performance, particularly when

abrasive feeds are involved, and also consider the fact that hygroscopic products can build up within

pipe walls. Be proactive, and check on any changes in system performance to avoid problems later on.

Elizabeth Knight is a senior consultant and Dr. Don McGlinchey is a consulting

engineer at Glasgow Caledonian University’s (GCU) Center for Industrial Bulk Solids Handling,

Cowcaddens Road, Glascow G40BA, U.IC. Tel:44(0) 141-331-3715. Contact them via E-mail at

e.knight@ gcal.ac.uk; and d.mcglinchey @gcal.ac.uk.

The authors wish to recognize the contribution made to this article by their esteemed colleague, Dr.

Pedrag Marjanovic, who, the authors note with sadness, has since passed away. Dr. Marjanovic was a

specialist in pneumatic conveying and bulk solids, and had

been a professor at Glasgow Caledonian since 1999.

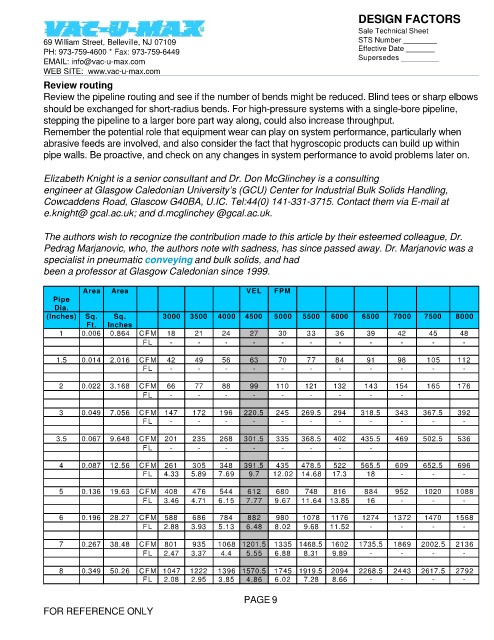

Area Area VEL FPM

Pipe

Dia.

(Inches) Sq. Sq. 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500 8000

Ft. Inches

1 0.006 0.864 CFM 18 21 24 27 30 33 36 39 42 45 48

FL - - - - - - - - - - -

1.5 0.014 2.016 CFM 42 49 56 63 70 77 84 91 98 105 112

FL - - - - - - - - - - -

2 0.022 3.168 CFM 66 77 88 99 110 121 132 143 154 165 176

FL - - - - - - - - -

3 0.049 7.056 CFM 147 172 196 220.5 245 269.5 294 318.5 343 367.5 392

FL - - - - - - - - - - -

3.5 0.067 9.648 CFM 201 235 268 301.5 335 368.5 402 435.5 469 502.5 536

FL - - - - - - - -

4 0.087 12.56 CFM 261 305 348 391.5 435 478.5 522 565.5 609 652.5 696

FL 4.33 5.89 7.69 9.7 12.02 14.68 17.3 18 - - -

5 0.136 19.63 CFM 408 476 544 612 680 748 816 884 952 1020 1088

FL 3.46 4.71 6.15 7.77 9.67 11.64 13.85 16 - - -

6 0.196 28.27 CFM 588 686 784 882 980 1078 1176 1274 1372 1470 1568

FL 2.88 3.93 5.13 6.48 8.02 9.68 11.52 - - - -

7 0.267 38.48 CFM 801 935 1068 1201.5 1335 1468.5 1602 1735.5 1869 2002.5 2136

FL 2.47 3.37 4.4 5.55 6.88 8.31 9.89 - - - -

8 0.349 50.26 CFM 1047 1222 1396 1570.5 1745 1919.5 2094 2268.5 2443 2617.5 2792

FL 2.08 2.95 3.85 4.86 6.02 7.28 8.66 - - - -

PAGE 9

FOR REFERENCE ONLY