Page 3045 - Flipbook_SolidDesignSoutheast2020

P. 3045

DESIGN FACTORS

Sale Technical Sheet

69 William Street, Belleville, NJ 07109 STS Number ________

PH: 973-759-4600 * Fax: 973-759-6449 Effective Date _______

EMAIL: info@vac-u-max.com Supersedes _________

WEB SITE: www.vac-u-max.com

Pneumatic conveying is essentially a very simple process, but the design factors that influence system

performance are varied and complex. Most component specifications are based on data resulting from

pipeline design. Since the data used in pipeline design are not totally reliable, many systems incorporate

margins and factors to allow for uncertainties. Use of these "fudge factors" often leads to a mismatch

between components and over-design in certain areas. Although over-design will generally ensure that a

system will work, it will rarely work efficiently.

Since the reasons for an under performing system are not always obvious, we need to examine the likely

causes of throughput difficulties, which result in frequent blockages, inability to convey a given product,

and systems that fail to meet required duty.

Clogged arteries

One of the most serious and frustrating problems in system operation is pipeline blockage. To rule out

blockage, check the obvious features:

o Is the reception point clear?

o Are the diverter valves operating satisfactorily?

o Is the full conveying air supply available?

o Was the pipeline clear on start-up?

If the pipeline blocks during commissioning trials with the pneumatic conveying system, either there is a

serious system design fault or some simple adjustment needs to be made.

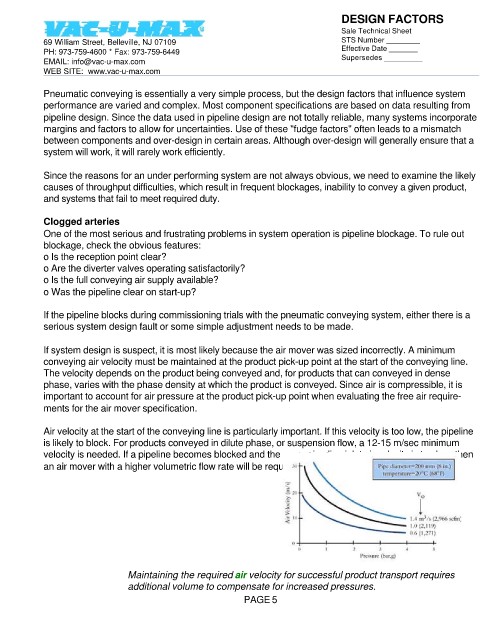

If system design is suspect, it is most likely because the air mover was sized incorrectly. A minimum

conveying air velocity must be maintained at the product pick-up point at the start of the conveying line.

The velocity depends on the product being conveyed and, for products that can conveyed in dense

phase, varies with the phase density at which the product is conveyed. Since air is compressible, it is

important to account for air pressure at the product pick-up point when evaluating the free air require-

ments for the air mover specification.

Air velocity at the start of the conveying line is particularly important. If this velocity is too low, the pipeline

is likely to block. For products conveyed in dilute phase, or suspension flow, a 12-15 m/sec minimum

velocity is needed. If a pipeline becomes blocked and the conveying line inlet air velocity is too low, then

an air mover with a higher volumetric flow rate will be required.

Maintaining the required air velocity for successful product transport requires

additional volume to compensate for increased pressures.

PAGE 5