Page 3048 - Flipbook_SolidDesignSoutheast2020

P. 3048

DESIGN FACTORS

Sale Technical Sheet

69 William Street, Belleville, NJ 07109 STS Number ________

PH: 973-759-4600 * Fax: 973-759-6449 Effective Date _______

EMAIL: info@vac-u-max.com Supersedes _________

WEB SITE: www.vac-u-max.com

If the system cannot achieve its rated duty, determine whether the problem is due to product feeding,

pipeline or air supply. Check on the conveying line pressure drop. If it is below the air mover’s capabil-

ity, product feed into the pipeline may be insufficient. If the maximum output of the feeder does not meet

the conveying capability of the pipeline, however, it will probably be necessary to fit a larger feeder.

Before recommending a larger feeder, be sure that air leakage isn’t the real culprit. Check rotary valves

in particular, as well as air vents and clearances on all moving parts. Don’t forget to check the filtration

unit. If it has been incorrectly sized, pressure drop across the filter may be too high. Also check that the

filter cloths don’t need replacing or cleaning. It may be that an additional or a larger filter is needed. If

these modifications don’t bring the system to rated output, an air mover with a higher pressure rating or

an increase in pipeline bore are indicated, but be sure to consider how this will influence other parts of

the system.

Reducing air flow Rate

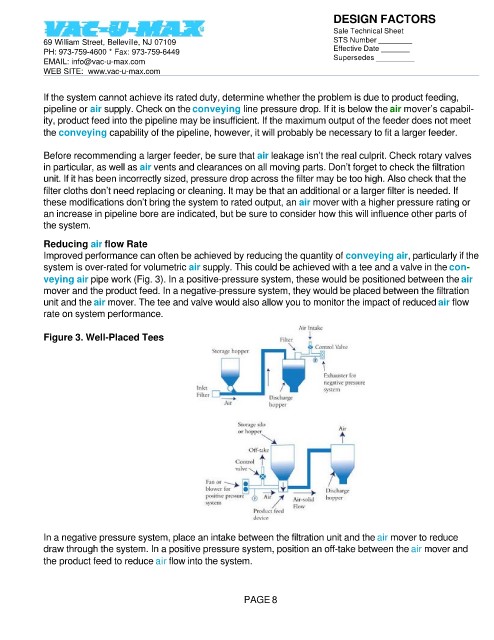

Improved performance can often be achieved by reducing the quantity of conveying air, particularly if the

system is over-rated for volumetric air supply. This could be achieved with a tee and a valve in the con-

veying air pipe work (Fig. 3). In a positive-pressure system, these would be positioned between the air

mover and the product feed. In a negative-pressure system, they would be placed between the filtration

unit and the air mover. The tee and valve would also allow you to monitor the impact of reduced air flow

rate on system performance.

Figure 3. Well-Placed Tees

In a negative pressure system, place an intake between the filtration unit and the air mover to reduce

draw through the system. In a positive pressure system, position an off-take between the air mover and

the product feed to reduce air flow into the system.

PAGE 8