Page 172 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 172

2) Solvent Bonding: Solvent-borne adhesives find use in specialized applications

where waterborne or hot-melt systems do not meet the technical requirements. The

joining parts are held under pressure whereas solvent causes the material to swell

and soften at the area of application. As the solvent evaporates, the interlocked

surfaces harden to create a permanent bond. Solvent bonding is effective only if

the materials being joined are soluble with the same solvent or in a mixture of

solvents.

However, factors of cost, safety (Solvents are often flammable and vapours may

be toxic and explosive), productivity and above all, compliance with clean-air law

have led to a strong movement towards waterborne or hot-melt alternatives.

Adhesives can be used to bond like or unlike plastics together and can also

bond plastics to foreign materials such as metals, wood and ceramics.

Different adhesives used are cyanoacrylate, urethane adhesives, epoxy adhesive,

silicone adhesives and others.

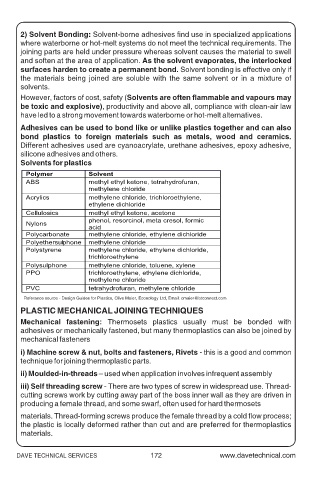

Solvents for plastics

Polymer Solvent

ABS methyl ethyl ketone, tetrahydrofuran,

methylene chloride

Acrylics methylene chloride, trichloroethylene,

ethylene dichloride

Cellulosics methyl ethyl ketone, acetone

Nylons phenol, resorcinol, meta cresol, formic

acid

Polycarbonate methylene chloride, ethylene dichloride

Polyethersulphone methylene chloride

Polystyrene methylene chloride, ethylene dichloride,

trichloroethylene

Polysulphone methylene chloride, toluene, xylene

PPO trichloroethylene, ethylene dichloride,

methylene chloride

PVC tetrahydrofuran, methylene chloride

Referance source - Design Guides for Plastics, Clive Maier, Econology Ltd, Email: cmaier@btconnect.com

PLASTIC MECHANICAL JOINING TECHNIQUES

Mechanical fastening: Thermosets plastics usually must be bonded with

adhesives or mechanically fastened, but many thermoplastics can also be joined by

mechanical fasteners

i) Machine screw & nut, bolts and fasteners, Rivets - this is a good and common

technique for joining thermoplastic parts.

ii) Moulded-in-threads – used when application involves infrequent assembly

iii) Self threading screw - There are two types of screw in widespread use. Thread-

cutting screws work by cutting away part of the boss inner wall as they are driven in

producing a female thread, and some swarf, often used for hard thermosets

materials. Thread-forming screws produce the female thread by a cold flow process;

the plastic is locally deformed rather than cut and are preferred for thermoplastics

materials.

DAVE TECHNICAL SERVICES 172